Recently, an 18-roller wire straightener focusing on precise straightening and wide adaptability has been officially launched. With its user-friendly design and durable performance, it provides a new option for processing 4-7mm metal wires.

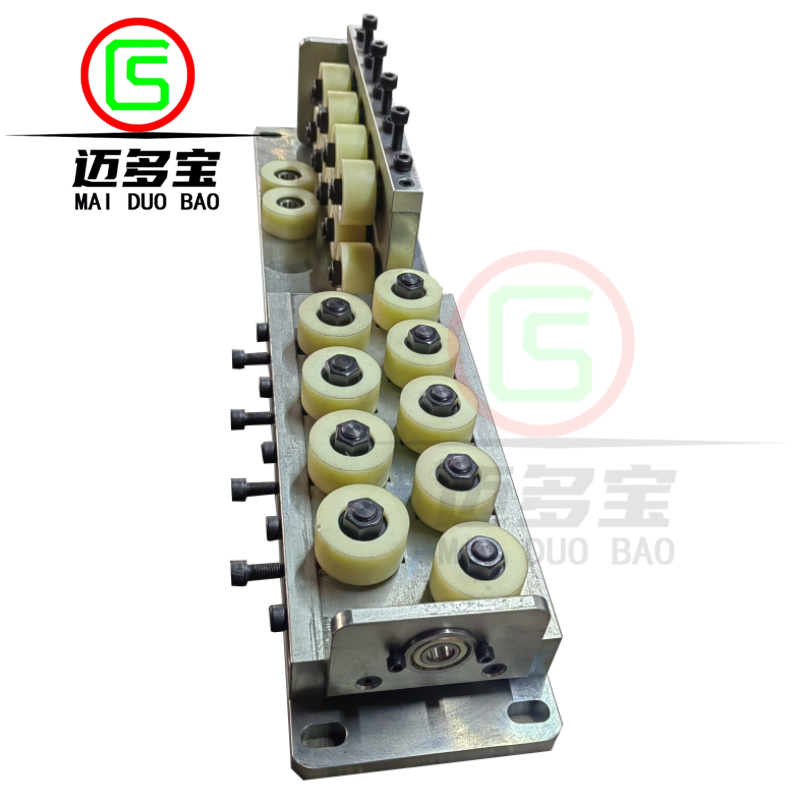

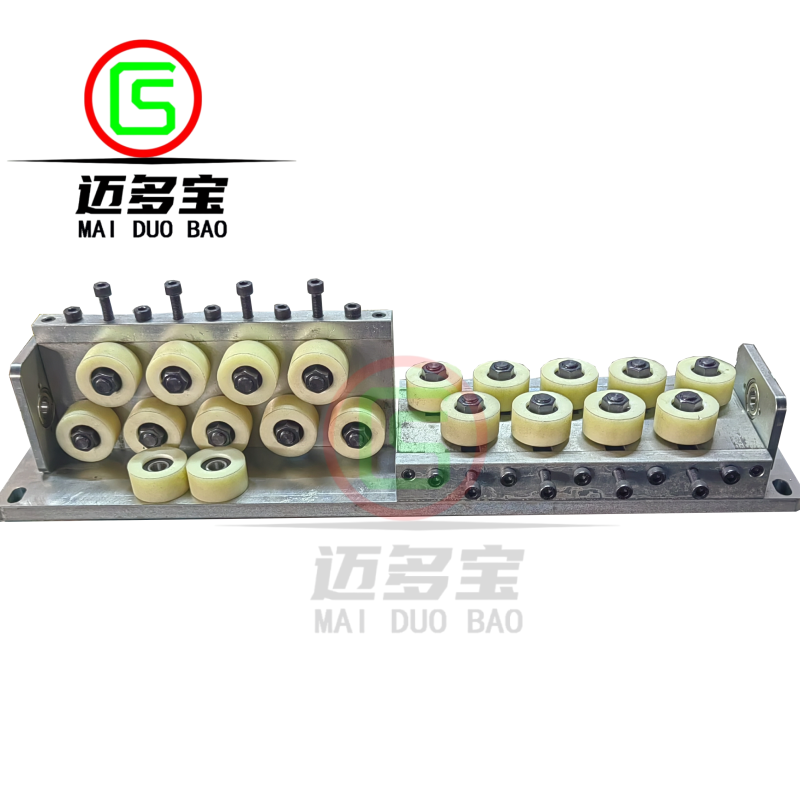

The core straightening structure of this equipment adopts 18 PA66 nylon rollers with an outer diameter of 42mm, which combines wear resistance and flexibility to reduce surface damage to the wire during the straightening process. The double-sided adjustment design allows operators to accurately adjust parameters according to the bending degree of the wire, and it is compatible with various materials such as steel wires, copper wires, nickel wires, iron wires and titanium wires, covering the mainstream metal wire processing needs.

The equipment has outstanding advantages in operation and practicality: a digital display screen is installed on the top, which can record and display adjustment data in real time, facilitating parameter traceback and standardized operations; the equipped hand crank can easily control the opening and closing of the rollers, simplifying the wire threading process. At the same time, the whole machine adopts a nickel plating process, which not only effectively improves the rust resistance and extends the service life of the equipment, but also integrates better into the layout of the customer's existing production line with its exquisite appearance.

The launch of this 18-roller wire straightener provides an efficient and reliable wire straightening solution for industries such as hardware manufacturing and precision parts, helping enterprises improve processing accuracy and production efficiency.

www.gswinding.com

Suzhou Maiduobao Technology Co., Ltd.