Three-phase asynchronous motors are the backbone of modern industrial systems. Among them, pumps, fans, and compressors represent the most energy-intensive and widely used applications. The performance of these machines directly affects production stability, operating costs, and long-term sustainability. As efficiency standards tighten and industries pursue more reliable solutions, YE3 series three-phase asynchronous motors have become a preferred choice for such core equipment.

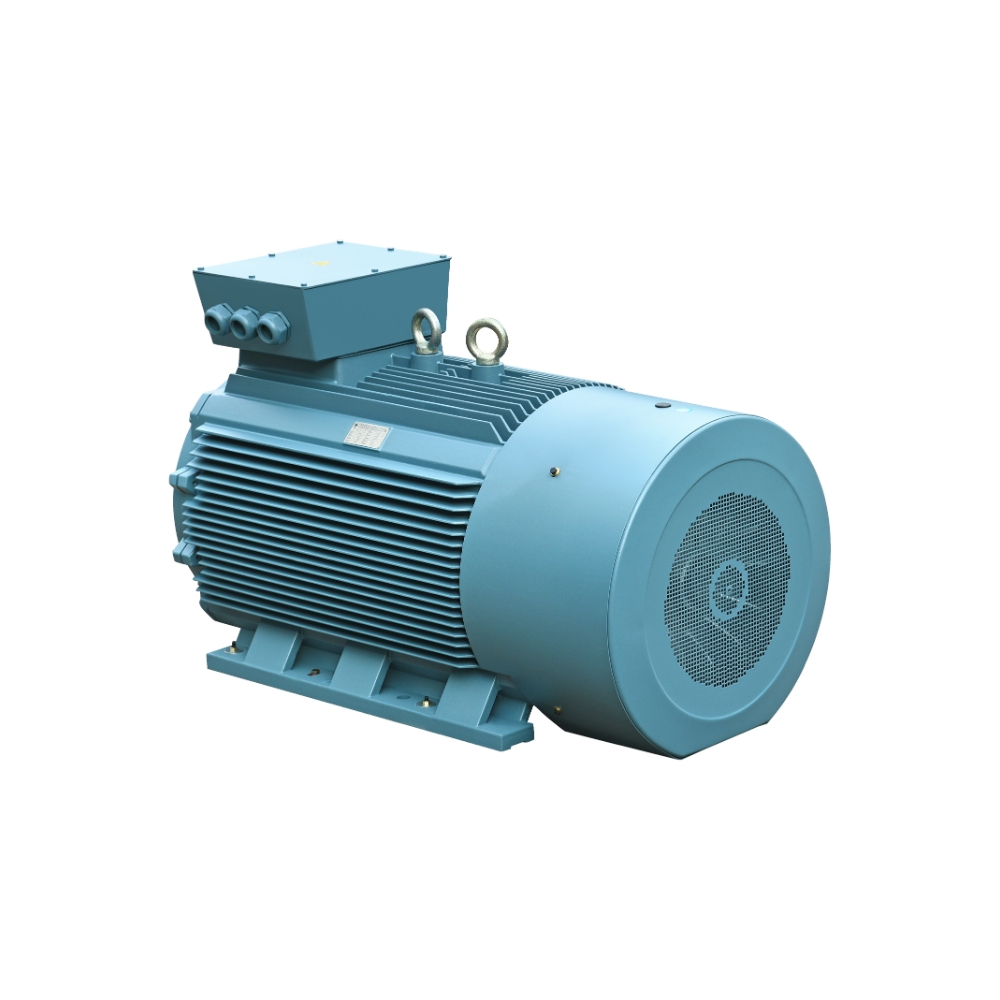

Independently developed by Zhejiang Aolong Motor Technology Co., Ltd., the YE3 series is designed to deliver high efficiency, stable operation, and long service life under real industrial conditions. This article explores how YE3 motors are applied in pumps, fans, and compressors, and why they are particularly well suited to these demanding applications.

Why Pumps, Fans, and Compressors Demand High-Quality Motors

Pumps, fans, and compressors often operate continuously or for extended daily cycles. In water treatment plants, HVAC systems, manufacturing lines, and process industries, these machines can account for a large proportion of total electricity consumption.

Their operating characteristics place specific demands on motors:

-

Frequent start and stop cycles

-

Long periods of steady operation

-

Variable loads depending on process conditions

-

High reliability requirements to avoid downtime

Motors that lack efficiency or thermal margin may suffer from excessive heat, vibration, or premature wear. Over time, this leads to higher energy consumption and increased maintenance. The YE3 series was developed specifically to address these challenges.

YE3 Series Motor Performance Overview

YE3 series three-phase asynchronous motors are high-efficiency, energy-saving products designed in accordance with modern technical standards. For frame sizes 63–355, they comply with GB/T28575, while larger frame sizes 355–400 meet JB/T10868 requirements. All YE3 motors achieve the Level 3 energy efficiency standard of GB18613-2020, consistent with IE3 efficiency classification under IEC 60034-30.

Beyond compliance, YE3 motors offer practical advantages including low vibration, excellent starting performance, a substantial temperature rise margin, and stable long-term operation. These characteristics are particularly valuable in pump, fan, and compressor applications.

Applications in Pump Systems

Pump systems are widely used in water supply, wastewater treatment, irrigation, chemical processing, and industrial circulation systems. Many pumps run around the clock, making motor efficiency and reliability critical.

YE3 motors improve pump performance in several ways:

First, high efficiency reduces power losses during continuous operation. Even modest efficiency improvements can result in significant energy savings over the lifecycle of a pump system.

Second, the excellent starting characteristics of YE3 motors help pumps reach operating speed smoothly. This reduces mechanical stress on couplings and impellers, especially in systems with frequent start-stop cycles.

Third, the substantial thermal margin ensures stable operation even under fluctuating loads or high ambient temperatures. In water conservancy and municipal projects, where environmental conditions can vary widely, this thermal stability directly contributes to longer service life.

As a result, YE3 motors are widely used in national water conservancy programs and energy-saving pump retrofitting projects.

Applications in Fan and Ventilation Systems

Fans and ventilation systems are essential in factories, power plants, tunnels, commercial buildings, and environmental protection facilities. These systems often operate under variable airflow demands and may run for long periods at partial load.

YE3 series motors are well suited to fan applications due to their stable torque characteristics and low vibration levels. Reduced vibration not only improves operational reliability but also helps maintain balanced airflow and reduce noise in ventilation systems.

High efficiency is particularly important in fan systems because power consumption increases rapidly with airflow. By minimizing electrical and mechanical losses, YE3 motors help operators achieve lower overall energy consumption while maintaining required ventilation performance.

In environmental protection projects, such as exhaust gas treatment and dust collection systems, the reliability of fan motors is critical. YE3 motors provide consistent performance and long service life, reducing the risk of unplanned shutdowns.

Applications in Compressor Systems

Compressors are among the most demanding applications for three-phase asynchronous motors. Whether used in refrigeration, air compression, or industrial gas systems, compressors typically require high starting torque and stable operation under load.

YE3 motors offer excellent starting performance, allowing compressors to start reliably even under pressure. This reduces the risk of overload and minimizes electrical stress during startup.

Once running, the high efficiency of YE3 motors ensures that compressors consume less energy for the same output. Over time, this leads to lower operating costs and improved system efficiency.

Thermal performance is another critical factor in compressor applications. YE3 motors are designed with optimized cooling and reduced internal losses, helping them maintain safe operating temperatures during prolonged operation. This contributes to longer bearing life and more stable insulation performance.

Replacement of Older Motor Series in Core Equipment

One of the practical advantages of YE3 motors is their ability to serve as full replacements for Y, YGM, YGM2, and YE2 series low-voltage three-phase asynchronous motors. In pump, fan, and compressor systems, this compatibility allows for straightforward upgrades without major changes to mechanical structures or control systems.

For many industrial users, replacing older motors with YE3 models is an effective way to improve energy efficiency and reliability while extending the service life of existing equipment. This approach is commonly adopted in energy conservation initiatives and industrial retrofitting projects.

Supporting Energy Conservation and Sustainable Operation

Energy efficiency improvements in pumps, fans, and compressors have a direct impact on overall industrial sustainability. By reducing electricity consumption, YE3 motors help lower carbon emissions associated with power generation.

This makes them well aligned with the goals of environmental protection projects and modern industrial policies. In sectors where energy audits and efficiency benchmarks are increasingly common, the use of IE3-class motors like the YE3 series is becoming a standard requirement.

Product Availability and Application Support

Zhejiang Aolong Motor Technology Co., Ltd. provides a wide range of YE3 series motors to meet diverse industrial needs. With multiple frame sizes, power ratings, and configurations available, YE3 motors can be matched precisely to pump, fan, and compressor requirements.

More information on available models and specifications can be found through the company’s product portfolio at:

https://www.alonmax.com/products

Practical Value in Real Industrial Environments

The widespread adoption of YE3 motors in pumps, fans, and compressors is driven by measurable benefits rather than theoretical claims. Lower energy consumption, improved thermal stability, reduced vibration, and extended service life all contribute to more efficient and reliable industrial operations.

For operators focused on long-term performance and compliance with modern standards, YE3 motors provide a practical solution that fits seamlessly into existing systems.

About Zhejiang Aolong Motor Technology Co., Ltd.

Zhejiang Aolong Motor Technology Co., Ltd. specializes in the development and manufacturing of high-performance electric motors for industrial applications. With a strong focus on efficiency, reliability, and standard compliance, the company supports customers across water treatment, manufacturing, environmental protection, and infrastructure sectors.

www.alonmax.com

Zhejiang Aolong Motor Technology Co., Ltd.