In the tire manufacturing industry, production efficiency, consistency, and safety have become decisive factors for competitiveness. As demand grows for motorcycle tires, agricultural tires, and industrial special tires, manufacturers are increasingly moving away from fragmented processes toward highly integrated solutions. The bias one stage tire building machine represents a significant step in this evolution, combining multiple processes into a single, automated workflow that reshapes how bias tires are produced. In this blog post, SONIWELL will share the role of automatic bias one stage tire building machines in plants, production processes, intelligent specification management, and more.

Role of Automatic Bias One Stage Tire Building Machine in Modern Plants

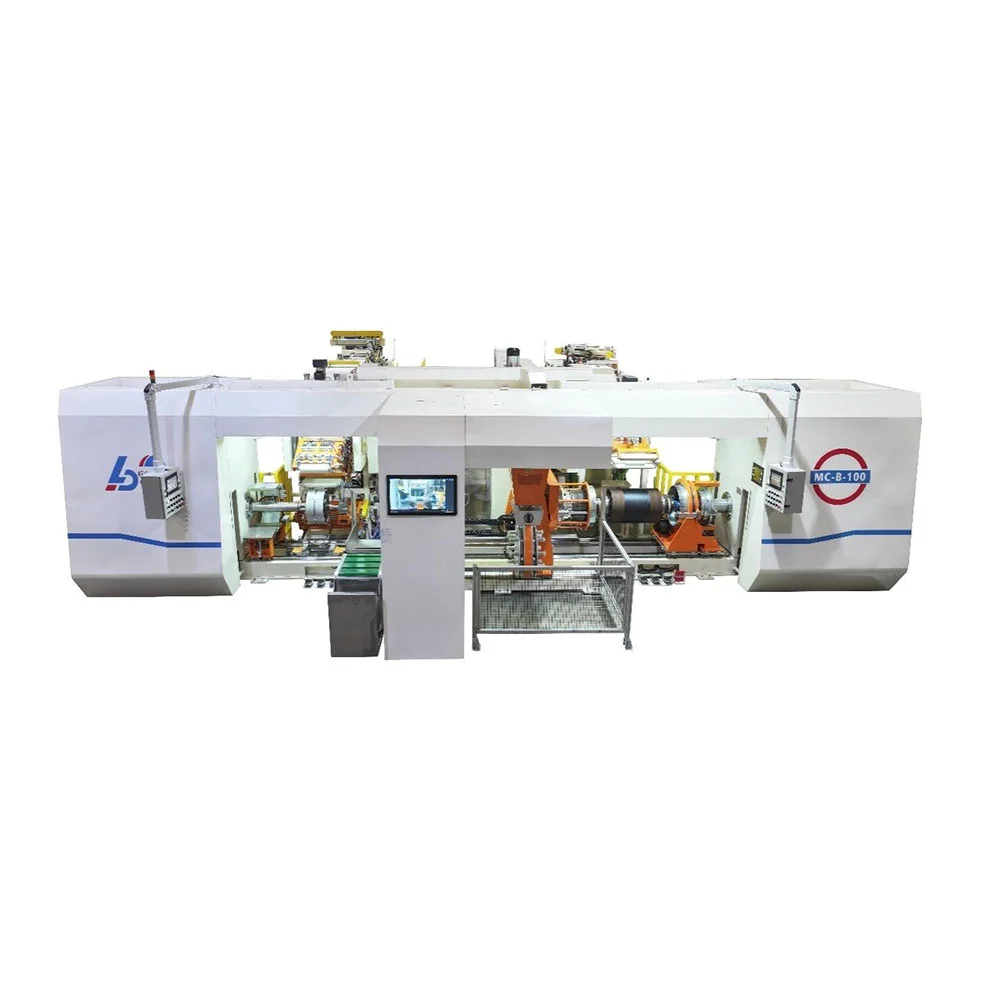

Traditional bias tire production often relies on multi-step processes, manual intervention, and repeated material handling. These factors increase labor intensity and introduce variability. An automatic bias one stage tire building machine consolidates forming operations into a one-step production process, allowing carcass building, material placement, and forming to occur in a single, continuous cycle.

By reducing intermediate transfers and alignment errors, the machine supports stable production rhythms while improving dimensional accuracy. This integrated role makes it especially suitable for factories pursuing lean manufacturing and standardized output across multiple tire specifications.

One-Step Production Logic and Process Integration

The defining characteristic of a one-stage bias tire builder is its one-step production process. Instead of dividing carcass forming and shaping into separate stations, the machine completes these operations on a single carcass drum.

This integration delivers several structural benefits:

-

Reduced floor space requirements due to fewer auxiliary units

-

Shorter production cycles by eliminating intermediate handling

-

Improved synchronization between material feeding and drum rotation

The large roll spool design further enhances process continuity by accommodating longer material rolls, minimizing frequent material changes and downtime during batch production.

Intelligent Specification Management for Flexible Manufacturing

Modern tire plants must frequently switch between different sizes and structures. The automatic bias one stage tire building machine addresses this need through advanced management of matching methods, supporting more than 200 parameter combinations.

With one-click switching of specifications, operators can rapidly adjust settings such as material length, joint position, and layer sequence. This digital approach reduces reliance on manual recalibration and ensures consistency when transitioning between motorcycle tires, agricultural tires, and industrial special tires.

Such intelligent management not only improves flexibility but also supports traceability and standardized process control across multiple production lines.

Structural Design Supporting High Quality Output

Mechanical rigidity is fundamental to stable tire building. The integral welded mainframe provides a robust structural foundation, minimizing deformation under dynamic loads and long-term operation.

A key quality-enhancing component is the ball-wrapped carcass drum. Equipped with a vacuum suction port, it is particularly suitable for tires without liners, ensuring secure material positioning during forming. This design improves layer conformity and reduces defects associated with slippage or uneven tension.

Together, these structural features contribute to repeatable accuracy and long-term machine stability, critical for high-volume production environments.

Precision Feeding and Cutting in One Stage Tire Building

Material accuracy directly affects tire balance and durability. In an automatic bias one stage tire building machine, precision is achieved through a two-stage servo conveyor feeding system. This configuration improves fixed-length accuracy by maintaining controlled tension and synchronized feeding speeds.

Each layer of material benefits from:

-

Automatic fixed-length control

-

Automatic cutting to ensure consistent overlap and joint alignment

For tread processing, an ultrasonic cutter is employed. The heating of the material head and tail during cutting improves edge quality and bonding performance, reducing the likelihood of separation or weak joints during subsequent curing.

Built-In Quality Control and Carcass Joint Detection

Instead of relying solely on post-process inspection, modern equipment integrates quality monitoring directly into the building stage. The carcass joint detection system identifies common defects such as flash seams, incorrect angles, uneven head sizes, and missing paste.

By detecting issues in real time, the automatic bias one stage tire building machine prevents defective carcasses from progressing further in the production line. This proactive approach reduces material waste and lowers the cost associated with downstream rework or rejection.

Automation Design and Reduced Labor Intensity

Automation is not only about speed; it is also about consistency and ergonomics. A high degree of automation allows the machine to perform tasks that traditionally required manual handling, significantly lowering labor intensity.

Key automated functions include:

-

Movable inner support wire placement seat

-

Automatic drum loading of steel wire rings

-

Automatic drum loading of carcass

-

Automatic tire unloading after forming

These features reduce physical strain on operators while stabilizing cycle times. As a result, production becomes less dependent on operator skill levels and more on standardized machine performance.

Safety Architecture in Automatic Bias Tire Building Equipment

As automation increases, safety systems must evolve accordingly. The automatic bias one stage tire building machine incorporates multiple layers of protection to ensure safe operation.

Active safety ropes and various photoelectric switch configurations provide immediate response to abnormal movement or intrusion. Anti-scalding and anti-pinch designs protect operators during material handling and maintenance. Additionally, a safety light curtain is configured on the operation side to prevent accidental access to hazardous zones during active cycles.

Fault alarm prompts further enhance safety by clearly signaling abnormal conditions, enabling rapid troubleshooting and reducing unplanned downtime.

Application Scope Across Specialized Tire Segments

While flexibility is a core advantage, application breadth is equally important. This type of one-stage bias tire building system is suitable for manufacturing motorcycle tires, agricultural tires, and industrial special tires.

These segments share a need for robust carcass structures and precise layer placement but differ in size ranges and material combinations. The machine’s wide parameter range and intelligent control system allow it to adapt efficiently to these variations without compromising production stability.

Automation as Strategic Asset in Tire Manufacturing

Beyond immediate operational benefits, adopting an automatic bias one stage tire building machine reflects a broader strategic shift. Manufacturers are increasingly prioritizing automation not only to reduce costs but also to enhance quality assurance, production transparency, and workforce safety.

By integrating forming, cutting, detection, and handling into a unified platform, this equipment supports scalable manufacturing models capable of responding to fluctuating market demands.

Looking Ahead

As tire designs continue to diversify and customer expectations rise, integrated production solutions will play a central role in shaping factory layouts and investment decisions. The automatic bias one stage tire building machine demonstrates how thoughtful mechanical design, intelligent control, and comprehensive safety systems can converge in a single platform.

Rather than simply accelerating existing processes, this approach redefines how bias tires are built—moving toward fewer steps, higher consistency, and smarter automation that aligns with the future direction of the tire manufacturing industry.

www.soniwellgroup.com

SONIWELL