EN 10305-4 E355 tubes are made from high-quality carbon steel, providing strong and durable tubing for hydraulic systems. Manufacturers use seamless construction to ensure these tubes are tough and long-lasting. This high-quality carbon steel can withstand high pressure, making the tubes ideal for demanding environments. Engineers choose EN 10305-4 tubes for hydraulic and pneumatic systems in automotive, aerospace, and industrial machinery applications. The high-quality carbon steel ensures reliable performance under high pressure and harsh conditions.

Key Takeaways

-

EN 10305-4 E355 tubes are made from seamless carbon steel. This steel is high-quality and stays strong under pressure. It also works well in tough places.

-

The tubes must follow strict size and surface rules. These rules help the tubes fit just right. They also stop leaks in hydraulic and pneumatic systems.

-

Cold drawing and heat treatment make the tubes stronger. These steps also give the tubes smooth surfaces. Smooth tubes help fluids flow better.

-

Makers test each tube very carefully. This makes sure the tubes are safe and strong. It also helps them work well every time.

-

These tubes are used in many areas. You can find them in cars, planes, medical tools, and big machines. They last a long time and keep systems safe.

EN 10305 Overview

Standard Classification

The European standard 10305 explains rules for steel tubes used in precise jobs. EN 10305 has different tube types for special uses. EN 10305-1 talks about cold-drawn seamless tubes for accurate work. EN 10305-2 is about welded cold-drawn tubes. EN 10305-3 covers welded cold-finished tubes. EN 10305-4 is the main rule for seamless cold-drawn tubes with round shapes. These tubes are important for hydraulic and pneumatic power systems. EN 10305-5 is for welded cold-finished square and rectangular tubes. Every part of EN 10305 makes sure tubes have exact sizes and smooth surfaces.

EN 10305-4 has strict rules for seamless tubes in hydraulic transmission. These tubes need smooth insides and exact sizes. Makers use EN 10305-4 to make sure tubes work well in tough fluid power systems.

|

Type of Steel Tube |

Application / Characteristics |

|

|---|---|---|

|

EN 10305-1 |

Cold-drawn seamless tubes |

General precision steel tubes |

|

EN 10305-2 |

Welded cold-drawn steel tubes |

Precision welded tubes |

|

EN 10305-3 |

Welded cold-finished steel tubes |

Welded tubes with cold finishing |

|

EN 10305-4 |

Seamless cold-drawn steel tubes |

Hydraulic and pneumatic power systems; high precision, tight tolerances, smooth inner surface |

|

EN 10305-5 |

Welded cold-finished square and rectangular tubes |

Square and rectangular welded tubes |

BS EN 10305 Scope

BS EN 10305 is the British version of the European standard 10305. This rule explains how steel tubes should be delivered for precise engineering. EN 10305-4 is part of this rule for seamless tubes in hydraulic and pneumatic systems. The rule sets limits for tube size and thickness. This helps tubes meet tough needs for moving fluids. EN 10305-1, EN 10305-2, EN 10305-3, and EN 10305-5 are also in BS EN 10305. Each one is for different tube types and uses.

Makers often look at BS EN 10305 and other world standards. DIN 2391 and DIN 2394 from Germany, ASTM rules from the US, and DIN 17175 have similar rules. These rules focus on exact sizes and high quality, especially for hydraulic tubes. Because BS EN 10305 matches these other rules, engineers can pick tubes that meet world standards.

|

Standard |

Application |

Technical Requirements / Tolerances |

|---|---|---|

|

EN 10305-4 |

Seamless precision steel hydraulic tubes |

Tight dimensional tolerances, e.g., O.D. min. +/-0.03 mm, WT min. +/-0.03 mm |

|

DIN 2391 |

Seamless precision steel hydraulic tubes |

Similar tight tolerances as EN 10305-4 |

|

DIN 2394 |

Precision steel tubes |

Mentioned as equivalent standard |

|

EN 10305-1 |

Precision steel tubes |

Tolerances conforming closely to EN 10305-4 and DIN 2391 |

|

DIN 17175 |

Steel tubes for pressure purposes |

Listed as equivalent standard |

|

ASTM Standards |

Equivalent standards in the US |

Equivalent technical requirements implied |

EN 10305, including EN 10305-4, EN 10305-1, EN 10305-2, EN 10305-3, and EN 10305-5, is the main set of rules for precise tubes in Europe. BS EN 10305 makes sure tubes work for hydraulic, pneumatic, and industrial jobs all over the world.

High-Quality Carbon Steel Specs

E355 Chemical Composition

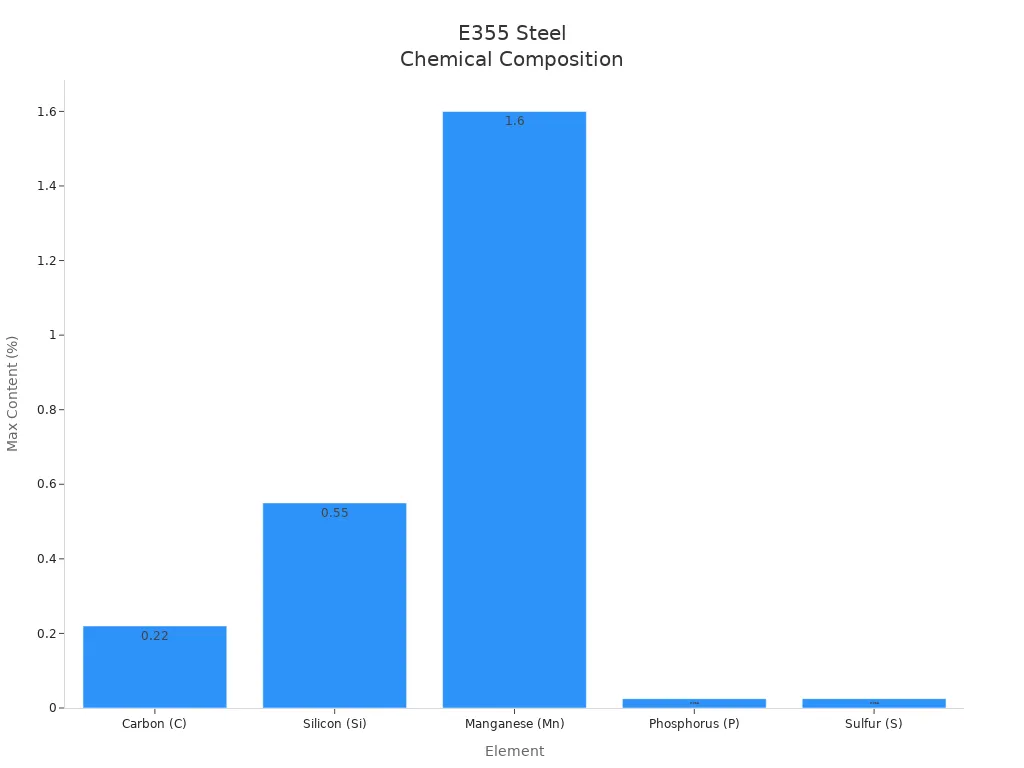

E355 is a strong carbon steel used in EN 10305-4 pipes. The mix of elements in E355 helps balance strength and flexibility. The European standard 10305 sets rules for each element. These rules help keep the steel quality the same every time. Makers follow these rules to make pipes for hydraulic and pneumatic systems.

|

Element |

Maximum Content (%) |

|---|---|

|

Carbon (C) |

|

|

Silicon (Si) |

0.55 |

|

Manganese (Mn) |

1.60 |

|

Phosphorus (P) |

0.025 |

|

Sulfur (S) |

0.025 |

Low phosphorus and sulfur levels stop the steel from breaking easily. They also help the steel join together better when welded. Manganese and silicon make the steel stronger and tougher. This makes E355 good for pipes that handle high pressure.

Mechanical Properties

EN 10305 steel pipes have strong mechanical properties. This makes them great for tough hydraulic jobs. E355 grade is known for high yield and tensile strength. These features help pipes hold up under high pressure.

|

Property |

E355 (EN 10305-1 & 4) |

|---|---|

|

Yield Strength (ReH) |

355 MPa (min) |

|

Tensile Strength (Rm) |

490–630 MPa |

|

Elongation (A) |

22% (min) |

|

Impact Energy (ISO-V) |

27 J at 20°C (min) |

-

About Author