The textile dyeing industry is undergoing a significant transformation driven by sustainability requirements, rising energy costs, and increasing demand for consistent quality. Traditional dyeing methods are being challenged by modern technologies that focus on efficiency, reduced resource consumption, and process stability. Among these innovations, multi-flow dyeing systems are emerging as a key solution for the future of textile dyeing.

The Shift Toward Sustainable Dyeing Practices

Sustainability has become a core requirement for textile manufacturers worldwide. Regulations, brand expectations, and consumer awareness are pushing dye houses to reduce water usage, chemical discharge, and energy consumption.

Modern dyeing machines are expected to:

Minimize water and liquor ratios

Reduce chemical waste and effluent load

Improve dye uptake efficiency

Lower overall energy consumption

Multi-flow dyeing technology directly supports these goals by optimizing fabric movement and dye circulation. Instead of relying on a single flow pattern, multi-flow systems allow precise control over dye penetration, reducing reprocessing and improving consistency.

Why Multi-Flow Dyeing Technology Matters

Traditional dyeing machines often struggle with uneven dyeing, especially when processing delicate or lightweight fabrics. Uneven fabric movement can result in shade variation, creasing, or fabric damage.

Multi-flow dyeing machines address these issues by:

Using multiple controlled dye flow paths

Allowing flexible adjustment for different fabric types

Ensuring uniform dye penetration across the fabric surface

This approach improves repeatability and allows dye houses to process a wider range of textiles with fewer machine changes.

Energy Efficiency as a Competitive Advantage

Energy efficiency is no longer just a cost-saving measure; it is a competitive advantage. Dyeing operations that consume less steam and electricity can respond better to market pressures and sustainability audits.

Future dyeing equipment trends focus on:

Shorter heating and cooling cycles

Optimized liquor circulation

Reduced friction and mechanical stress

The DBAL-K Multi-Flow Dyeing Machine is designed to support these requirements by balancing mechanical movement with efficient dye flow. This reduces unnecessary energy loss while maintaining stable dyeing conditions.

Flexibility for Diverse Fabric Applications

Textile production today is more diversified than ever. Dye houses must process cotton, polyester, blends, functional fabrics, and technical textiles—often in small batches.

Future dyeing machines must offer:

High adaptability across fabric weights and constructions

Stable performance in short production runs

Easy parameter adjustment for different dyeing recipes

Multi-flow dyeing technology allows operators to fine-tune fabric movement and dye flow according to fabric characteristics. This flexibility helps manufacturers reduce downtime and increase overall productivity.

Automation and Process Control Trends

Automation is becoming a standard feature in modern dyeing facilities. Intelligent control systems help reduce human error, improve consistency, and collect valuable production data.

Key automation trends include:

Digital recipe management

Real-time monitoring of temperature and flow

Automated fault detection and alerts

Multi-flow dyeing machines are well-suited for automation because they offer predictable and controllable dye circulation patterns. This enables better integration with modern control systems and smart factory initiatives.

Quality Consistency and Reduced Rework

One of the biggest challenges in textile dyeing is rework caused by shade inconsistency or fabric defects. Re-dyeing increases costs, wastes resources, and delays delivery schedules.

Future dyeing solutions aim to:

Improve first-pass yield

Minimize shade deviation

Protect fabric structure

Multi-flow dyeing machines help achieve these goals by maintaining consistent dye contact and gentle fabric handling. This results in better color uniformity and reduced mechanical stress on the fabric.

Meeting Global Compliance Standards

Global textile markets require strict compliance with environmental and quality standards. Dyeing machines must support compliance with regulations related to water discharge, chemical usage, and workplace safety.

Modern dyeing equipment trends emphasize:

Lower environmental impact

Safer operating conditions

Easier documentation and traceability

Dongbao Dyeing Machine designs its systems with international compliance in mind, ensuring that dye houses can meet export and certification requirements more efficiently.

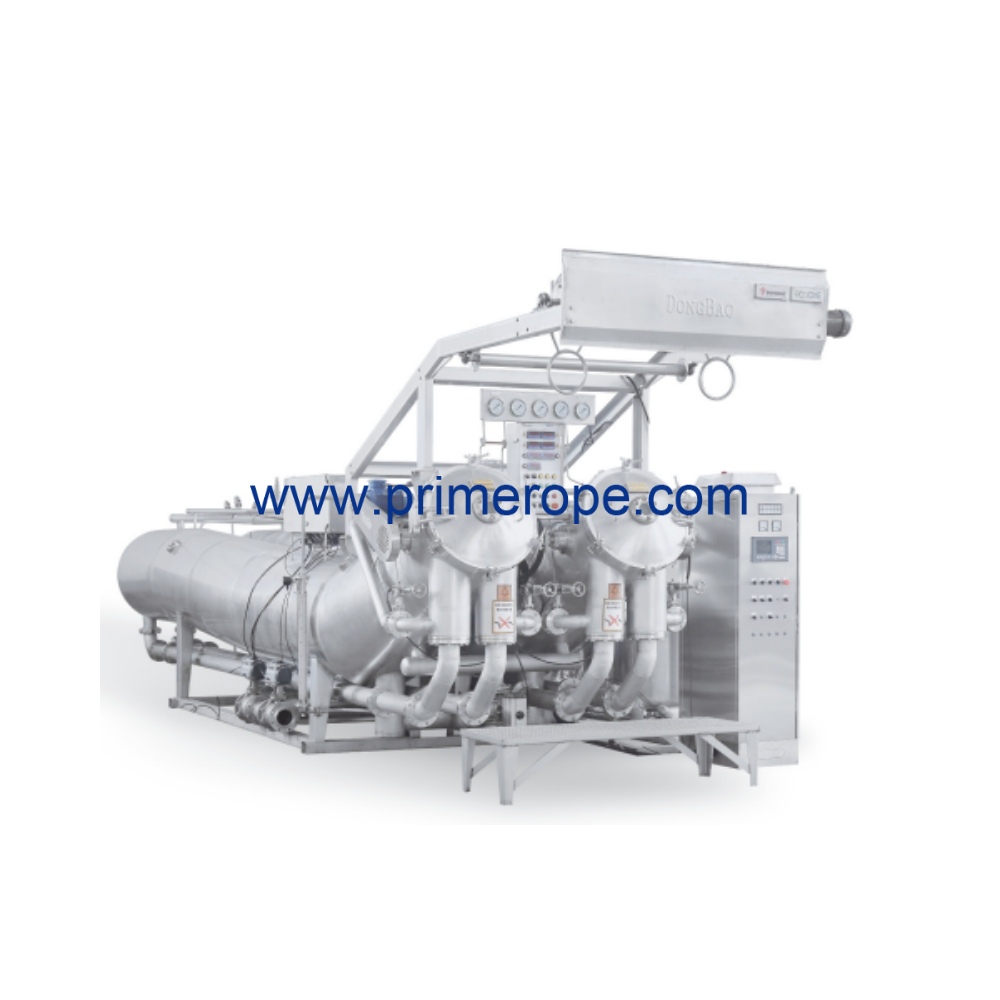

The Role of DBAL-K Multi-Flow Dyeing Machines in Future Dye Houses

As dye houses modernize, investment decisions increasingly focus on long-term performance rather than short-term cost savings. Machines that offer durability, adaptability, and process stability are more likely to deliver long-term value.

The DBAL-K Multi-Flow Dyeing Machine aligns with future industry trends by offering:

Controlled multi-flow dye circulation

Energy-efficient operation

Versatility for various fabric types

Stable and repeatable dyeing results

These features make it a practical choice for manufacturers looking to upgrade their dyeing operations while meeting sustainability and quality expectations.

Conclusion

The future of textile dyeing depends on technologies that balance efficiency, sustainability, and product quality. Multi-flow dyeing systems represent a significant step forward, addressing many of the limitations of traditional dyeing methods.

By adopting advanced solutions such as the DBAL-K Multi-Flow Dyeing Machine, dye houses can improve operational efficiency, reduce environmental impact, and deliver consistent, high-quality dyed fabrics. As industry standards continue to evolve, multi-flow dyeing technology is expected to play an increasingly important role in modern textile production.

www.primerope.com

Dongbao Machinery