In recent years,with flat masks becoming indispensable across sectors such as healthcare, manufacturing, education, and public services. As the need for high-quality, disposable face masks continues to grow, manufacturers are turning to more efficient and reliable production methods. This is where the Flat Mask Machine plays a vital role—offering an automated, high-speed solution for producing large volumes of flat masks with consistency, precision, and minimal labor input.

As a high-tech enterprise specializing in research and development, manufacturing, and sales, Broadfair leads the way in intelligent mask production machinery. Their flat mask machine solutions are engineered for performance, speed, and precision—offering clients a fully automated approach to mass-producing disposable masks with consistency and quality.

What Is a Flat Mask Machine?

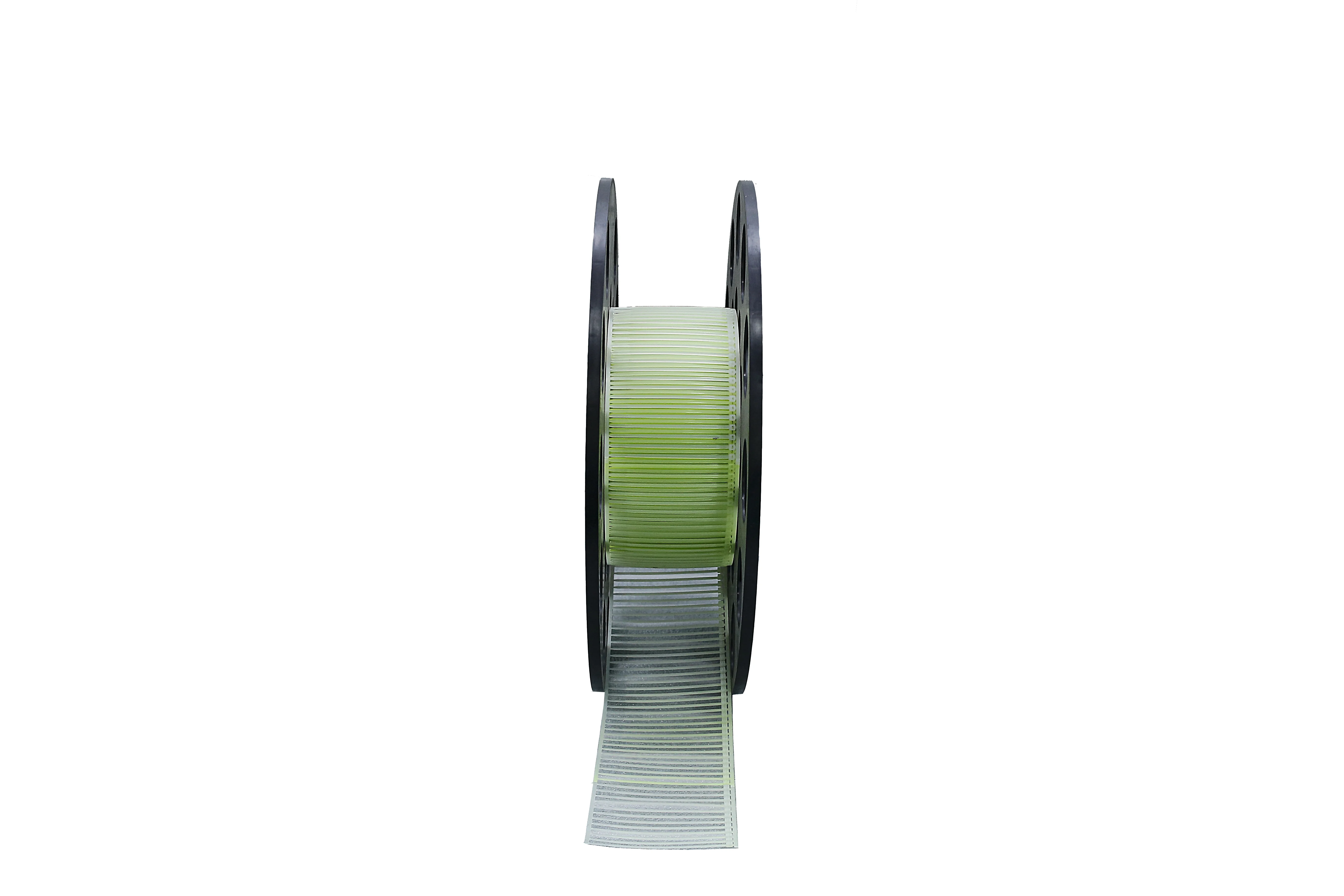

A flat mask machine, also known as a surgical mask machine or 3-ply mask machine, is an automated piece of equipment designed to manufacture disposable flat face masks. The masks typically consist of three or more layers—outer non-woven fabric, a melt-blown filtration layer, and an inner skin-friendly layer. These masks are used extensively in medical settings, public transport, industrial workplaces, and everyday life.

The fully automatic flat mask production line from Broadfair integrates every step of the process—from raw material feeding to ear loop welding and mask stacking—into a continuous, high-speed workflow.

How Does a Flat Mask Machine Work?

The flat mask machine production line consists of several coordinated modules, each performing a specific task:

Material Feeding

Multiple rolls of non-woven and melt-blown fabric are automatically unwound and aligned. This forms the base structure of the mask.

Layer Folding and Nose Clip Insertion

The machine folds the fabric into the pleated mask shape while simultaneously inserting a nose wire for better fit and sealing.

Ultrasonic Welding of Mask Body

Using ultrasonic technology, the machine welds the fabric layers together to form the basic mask body—strong, clean, and without the need for adhesives.

Ear Loop Welding

In a fully automatic setup, robotic arms weld elastic ear loops onto the mask body quickly and accurately.

Cutting and Stacking

The machine cuts each mask to uniform size and stacks them for easy packaging—fully ready for the next stage of distribution.

All of these operations are managed through an intelligent PLC control system with real-time monitoring, fault detection, and performance optimization.

Key Features of Broadfair's Flat Mask Machine

Broadfair integrates cutting-edge technology and engineering excellence into every aspect of its mask production lines:

1. Fully Automated Workflow

From material loading to finished mask stacking, the entire process is automated, reducing labor requirements and improving hygiene.

2. High-Speed Production

Broadfair’s machines can produce 80–150 masks per minute, enabling large-scale manufacturing for both domestic and international markets.

3. Advanced Ultrasonic Welding

Ultrasonic bonding ensures strong, precise joins for both the mask body and ear loops—improving both comfort and structural integrity.

4. Stable Operation and Low Failure Rate

With durable components and precision engineering, Broadfair machines offer long-term stable performance with minimal maintenance.

5. Customizable Configuration

Different mask sizes, colors, nose wire styles, and ear loop formats (inner or outer) can be configured to suit customer requirements.

6. User-Friendly Interface

A touchscreen control panel with multiple language support allows for easy operation and system diagnostics.

Applications of Flat Mask Machines

Flat mask production machines are widely used in:

Medical Supply Manufacturing

Pharmaceutical Companies

Public Health and Government Supply Chains

Factories and Industrial Workspaces

Retail and Private Label Brands

Broadfair’s advanced systems allow mask manufacturers to meet various compliance standards such as CE, FDA, or ISO with ease.

Why Choose Broadfair?

Broadfair is a trusted name in intelligent manufacturing systems, committed to technological innovation, quality assurance, and customer satisfaction. With strong capabilities in R&D, design, and production, Broadfair offers:

1. Tailor-made machinery based on client needs

2. Robust after-sales technical support

3. Competitive pricing with no compromise on quality

4. Timely delivery and global shipping options

5. Proven industry expertise in PPE and automation equipment

Whether you’re a startup entering the PPE market or a large-scale manufacturer looking to boost productivity, Broadfair delivers scalable and reliable flat mask machine solutions that fit your production goals.

Final Thoughts

The fully automatic flat mask machine is more than just a piece of equipment—it is a strategic asset in today’s fast-paced, safety-csion, and automation, it empowers manufacturers to produce high-quality masks that meet global standards.

Broadfair, as a leading high-tech enterprise in this field, continues to push boundaries with innovative machinery that enhances productivity, ensures quality, and drives long-term value for its partners.

Ready to scale your mask production capabilities? Contact Broadfair today to explore advanced flat mask machine solutions tailored to your needs.

The Role of Flat Mask Machines in Advancing Automated Mask Production

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.