In modern industrial environments, filtration systems are critical for ensuring operational safety, product purity, and environmental compliance. From air filtration in manufacturing plants to liquid filtration in chemical processing, the performance of the filter media directly impacts efficiency, energy consumption, and maintenance costs.

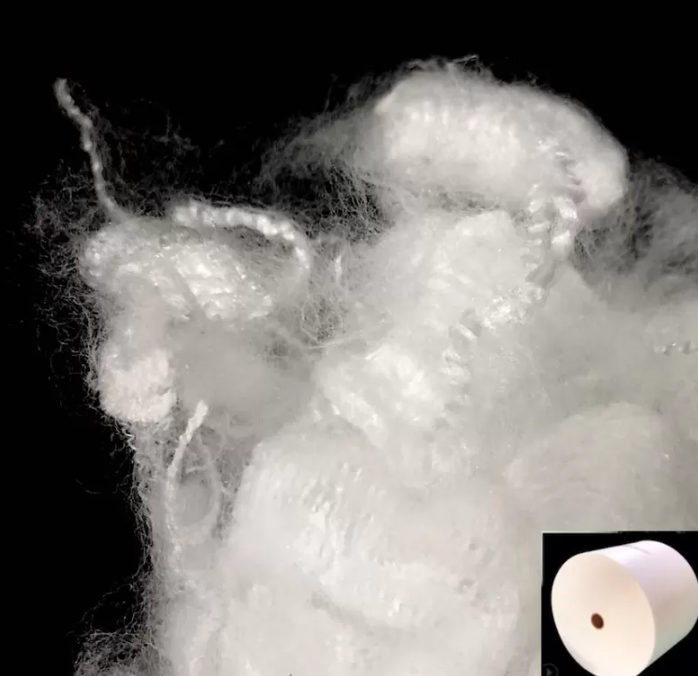

SuZhou Makeit Technology Co., Ltd, a leading producer of polyester and polypropylene staple fibers, leverages decades of fiber innovation and industrial experience to manufacture electrostatic non woven polypropylene (PP) fibers optimized for high-efficiency filtration. These fibers combine intrinsic chemical resistance, resilience, and lightweight properties with electrostatic charging technology, delivering superior particle capture and long-term operational reliability.

Electrostatic Non Woven Polypropylene Fiber: Core Advantages

1. Lightweight and High Resilience

Polypropylene fiber’s specific gravity of 0.91 g/cm³ makes it the lightest fiber used in industrial filter media. Its low density allows for high porosity media with minimal airflow resistance, reducing energy consumption in HVAC, dust collection, or liquid filtration systems. Additionally, its excellent resilience and dimensional stability ensure consistent fiber spacing, preventing collapse under high airflow or liquid pressure conditions.

2. Electrostatic Charge Capability

Electrostatic treatment enhances particle capture efficiency without increasing material thickness. The electrostatic charge attracts fine particulate matter—including PM2.5, aerosols, and microfibers—enabling high filtration efficiency at low pressure drop, a critical factor in industrial filtration where both throughput and energy efficiency are vital.

3. Chemical and Thermal Resistance

Polypropylene fibers exhibit high resistance to acids, alkalies, and organic solvents, making them suitable for industrial applications ranging from chemical processing to battery manufacturing. With heat-insulating properties and thermal stability, PP fibers maintain structural integrity under high-temperature operations, ensuring long-term filter performance without degradation.

4. Moisture Permeability and Quick Drying

PP fibers’ low moisture absorption ensures minimal water retention, preventing microbial growth and maintaining consistent electrostatic performance in humid or wet environments. Quick-drying properties also facilitate efficient maintenance and media replacement cycles.

Industrial Applications of Electrostatic Non Woven PP Fiber

Electrostatic non woven PP fibers are utilized across a wide spectrum of industrial filtration scenarios:

1. Air Filtration Systems

-

HVAC Systems in Factories: Capturing airborne particles, dust, and pollutants to maintain clean air for machinery and workforce safety.

-

Cleanroom Environments: Semiconductor, pharmaceutical, and food processing plants rely on ultra-fine PP fiber media to achieve ISO-classified air purity levels.

-

Dust Collection Units: PP fiber media with electrostatic properties enhances filtration efficiency while extending service life in heavy dust environments.

2. Liquid Filtration

-

Chemical Process Filtration: High chemical resistance allows PP fibers to filter corrosive or solvent-laden liquids without fiber degradation.

-

Water Treatment and Cooling Systems: Non woven PP fibers provide effective filtration of suspended solids while maintaining low flow resistance.

-

Battery Electrolyte Filtration: Ensures purity in lead-acid or lithium-ion battery manufacturing, improving product quality and lifecycle performance.

3. Specialty Industrial Applications

-

Oil Mist and Fume Collection: Electrostatic PP fibers efficiently capture oil mist in metalworking, machining, or automotive industries.

-

Food and Beverage Processing: PP fiber media meets food-grade safety requirements for capturing fine particulates in liquids, preserving hygiene standards.

-

Gas Filtration in Combustion or Emission Control: Lightweight electrostatic fibers reduce pressure drop while capturing micro particles in industrial exhaust gases.

Design Optimization for Maximum Filtration Efficiency

Maximizing efficiency in industrial filtration requires strategic fiber configuration and media design:

1. Fiber Diameter and Distribution

-

Fine-diameter fibers increase surface area, improving particle capture.

-

Multi-layered arrangements combine coarse support layers with ultra-fine electrostatic layers to balance mechanical strength with filtration efficiency.

2. Media Thickness and Porosity

-

Optimizing thickness ensures low airflow resistance while maintaining high particulate retention.

-

Porosity gradients allow larger particles to be trapped in initial layers, while fine layers capture sub-micron contaminants.

3. Electrostatic Charge Management

-

PP fibers retain electrostatic charges through corona discharge or triboelectric charging, maintaining high filtration efficiency over extended operational periods.

-

Media treatments can be optimized to sustain charge in high-humidity or chemically aggressive environments.

4. Layer Integration and Pleating

-

Pleated media increases the effective filtration area without increasing footprint.

-

Combining multiple non woven PP layers ensures durability, even under high-pressure airflow or liquid systems.

Sustainability and Maintenance Considerations

1. Longevity and Reduced Waste

-

Non woven PP fibers with electrostatic properties extend filter service life, reducing replacement frequency and minimizing waste.

-

Lightweight PP fiber media reduces shipping and handling energy costs, contributing to a lower carbon footprint.

2. Recyclability and Eco-Friendly Options

-

PP fibers are fully recyclable under industrial processes.

-

Makeit has developed bio-based PP alternatives compatible with electrostatic treatments, further advancing environmental sustainability.

3. Cleaning and Reuse

-

Some industrial filters can be partially cleaned via back-flushing or low-pressure air pulses, recovering media efficiency without complete replacement.

-

Electrostatic retention remains stable when fibers are properly conditioned, ensuring consistent performance over multiple cycles.

Frequently Asked Questions (FAQ)

Q1: How does electrostatic charge improve polypropylene fiber filtration?

A1: Electrostatic charges attract fine particles, enhancing capture efficiency without increasing fiber density or airflow resistance.

Q2: Can PP fibers be used for both air and liquid filtration?

A2: Yes. Their chemical resistance, hydrophobicity, and structural stability make them versatile for a wide range of industrial filtration applications.

Q3: What maintenance strategies maximize fiber lifespan?

A3: Periodic inspection, gentle cleaning, and controlled environmental conditions preserve electrostatic charge and structural integrity.

Q4: Are there sustainable PP fiber alternatives?

A4: Makeit develops biomass-derived fibers (PLA, PBS) that can partially replace petrochemical PP while maintaining performance and electrostatic compatibility.

Q5: What industrial conditions require electrostatic PP fibers?

A5: High-dust, chemical-laden, high-humidity, or high-temperature environments benefit most from electrostatic PP fiber filtration due to enhanced efficiency and durability.

Conclusion

Maximizing filtration efficiency in industrial applications demands careful selection of fiber properties, electrostatic performance, and media design. Electrostatic non woven polypropylene fibers produced by SuZhou Makeit Technology Co., Ltd provide an optimal combination of:

-

Lightweight, resilient fiber structure.

-

Electrostatic charge retention for fine particle capture.

-

Chemical, thermal, and moisture resistance.

-

Versatile applicability across air, liquid, and specialty industrial filtration.

-

Sustainability and reduced environmental footprint through extended service life and recyclable materials.

By integrating advanced fiber technology, electrostatic optimization, and sustainable design, industrial filtration systems achieve higher efficiency, lower energy costs, and extended operational reliability, supporting modern industrial requirements while maintaining environmental responsibility

www.makeitfiber.com

SuZhou Makeit Technology Co.,Ltd