https://www.jjmagnet.net/arc-magnet-manufacturing-process.html

The arc magnet manufacturing process plays a crucial role in ensuring the performance, durability, and efficiency of electric motors, generators, and magnetic couplings. Each stage of this process requires precision, advanced technology, and strict quality control. At Ningbo Jinji Strong Magnetic Material Co., Ltd., the complete arc magnet manufacturing process — from raw material preparation to final magnetization — is carefully managed to deliver products that meet the highest industrial standards.

1. Material Selection and Preparation

Every high-quality arc magnet manufacturing process begins with selecting premium neodymium, iron, and boron (NdFeB) raw materials. These are the foundation of strong and reliable magnetic performance.

At Ningbo Jinji, the materials are vacuum melted and precisely alloyed to maintain purity and consistency. The resulting alloy is crushed into fine powder, which forms the basis of the uniform magnetic properties required for arc-shaped magnets.

2. Pressing and Molding

In the next stage of the arc magnet manufacturing process, the powder is pressed into a specific arc shape using isostatic or die pressing technology. During this step, the magnetic orientation—radial or axial—is established.

Ningbo Jinji uses advanced magnetic field pressing equipment to ensure that the shape and orientation of every magnet precisely meet design requirements, achieving optimal performance in motor assemblies.

3. Sintering and Heat Treatment

Sintering is one of the most critical stages in the arc magnet manufacturing process. The pressed magnet is heated to around 1,050°C–1,100°C in a vacuum furnace, fusing the particles into a dense structure.

After sintering, the magnet undergoes heat treatment to relieve stress and improve mechanical stability. Ningbo Jinji’s controlled sintering environment ensures consistent coercivity and remanence across every batch of magnets.

4. Machining and Surface Finishing

Precision machining is essential for arc magnets, which must fit perfectly within curved motor housings.

At this stage of the arc magnet manufacturing process, Ningbo Jinji performs CNC grinding and laser measurement to maintain exact dimensional tolerances.

Surface treatments such as Ni-Cu-Ni plating, epoxy coating, or zinc plating are applied to prevent corrosion and extend service life, depending on customer specifications.

5. Magnetization

The final magnetic properties are achieved during the magnetization step of the arc magnet manufacturing process. Using advanced magnetizing fixtures and pulse power systems, the magnets are magnetized in the desired direction—multi-pole, radial, or segmental—to match the motor’s magnetic circuit.

Ningbo Jinji ensures precise and stable magnetization to deliver maximum performance in all types of electric and industrial motors.

6. Quality Control and Testing

Throughout the arc magnet manufacturing process, strict quality control is applied to every magnet.

Testing includes:

-

Flux density and magnetic field uniformity

-

Coercivity (HcJ) and remanence (Br)

-

Visual inspection and coating thickness measurement

-

Salt spray and high-temperature aging tests

All processes at Ningbo Jinji Strong Magnetic Material Co., Ltd. comply with ISO 9001, RoHS, and REACH standards, ensuring that customers receive magnets of consistent quality and reliability.

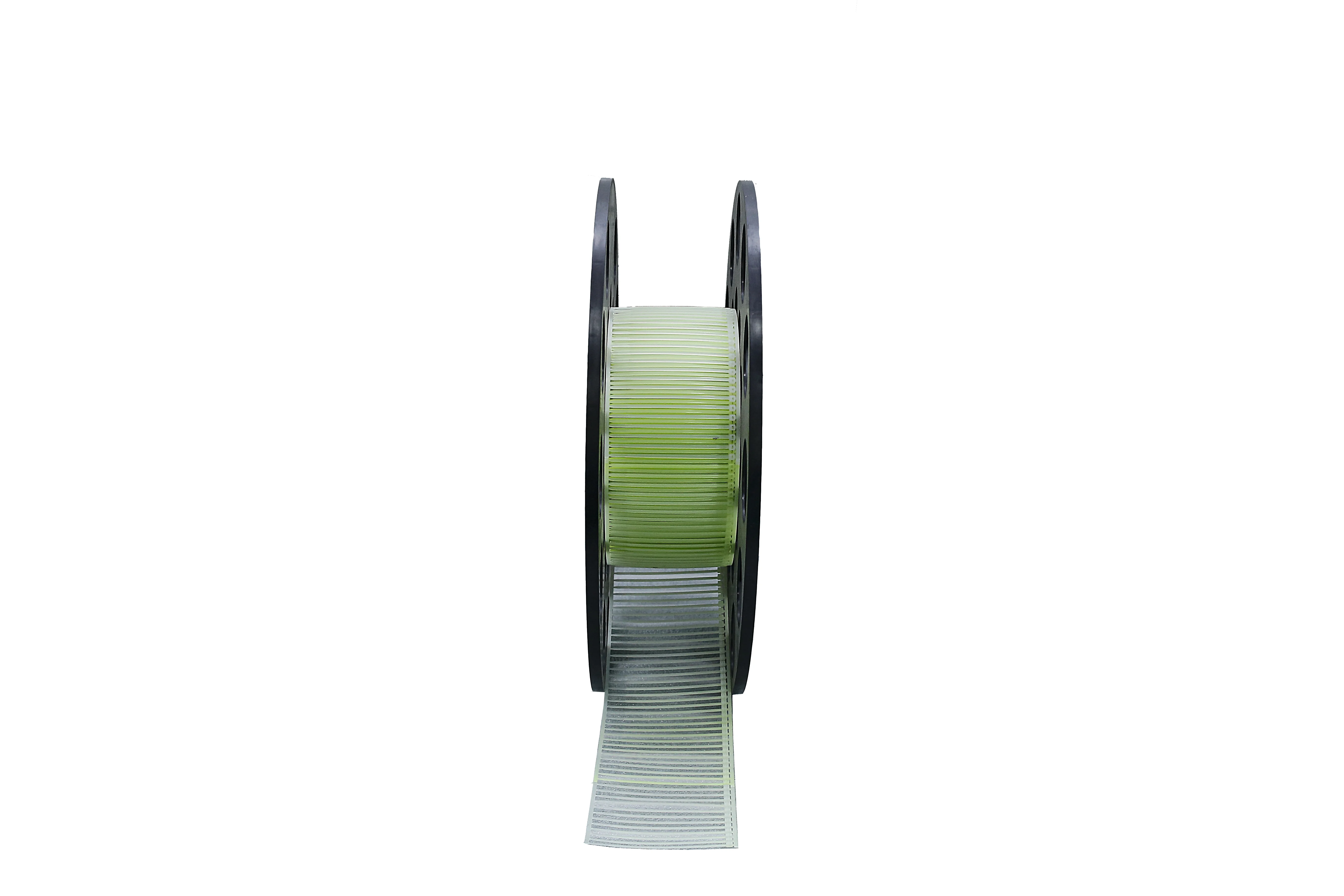

7. Packaging and Delivery

After completing the arc magnet manufacturing process, the finished magnets are safely packaged with anti-magnetic shielding and anti-corrosion protection to prevent damage during transportation.

With years of global export experience, Ningbo Jinji Strong Magnetic Material Co., Ltd. provides fast and secure delivery for customers in the motor, generator, and automation industries.

The arc magnet manufacturing process involves multiple precise stages — from material melting and powder preparation to pressing, sintering, machining, and magnetization.

By mastering every step of this process, Ningbo Jinji Strong Magnetic Material Co., Ltd. ensures that each arc magnet delivers high magnetic performance, exceptional consistency, and long-term stability for demanding industrial applications.

https://www.jjmagnet.net/arc-magnet-manufacturing-process.html

Ningbo Jinji Strong Magnetic Material Co., Ltd.