The Nissan GA14 engine, known for its reliability and fuel efficiency, is a cornerstone in the automaker's lineup. Ensuring optimal performance of this engine involves meticulous attention to detail, particularly in critical components such as piston rings. The piston rings customized for the GA14 engine are made of high-quality materials and are precisely machined to ensure that their size, hardness and wear resistance fully meet the unique requirements of the engine, thereby extending the engine service life and improving overall performance and fuel economy.

Understanding Piston Rings and Their Role

Function and Types

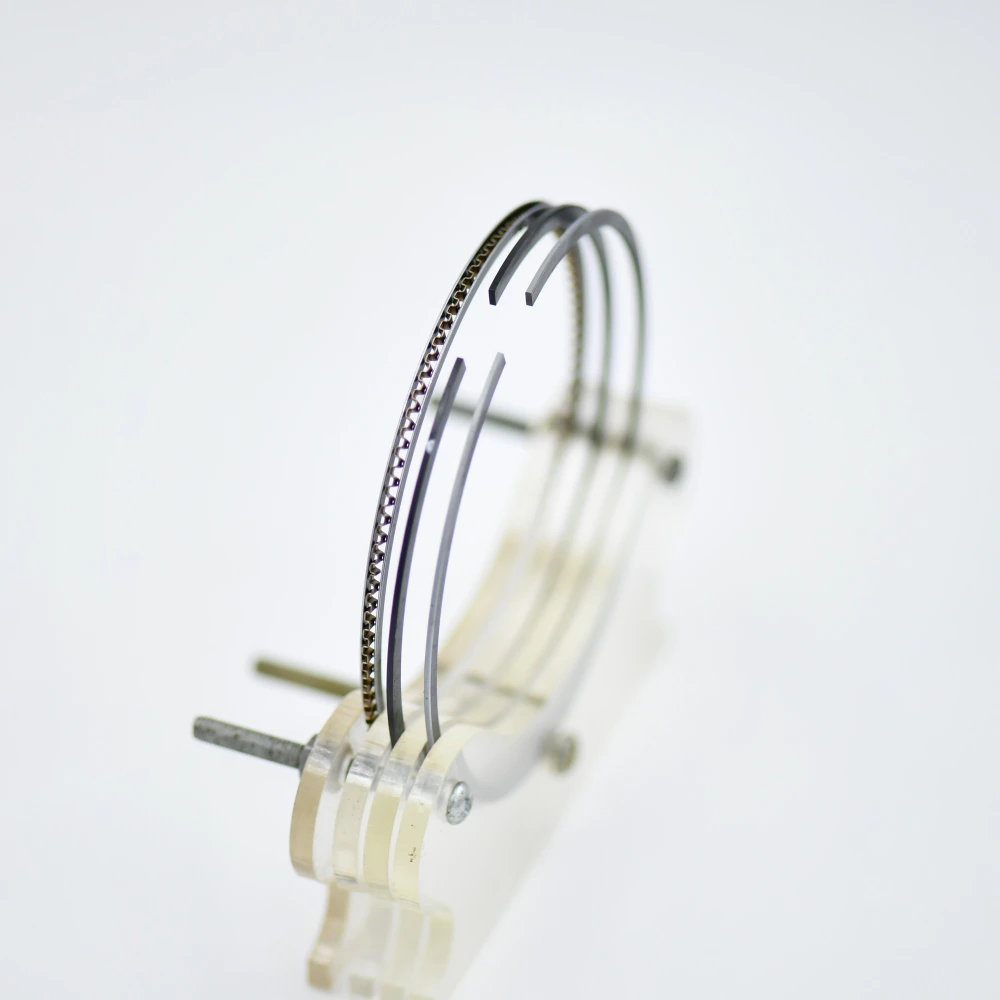

Piston rings are crucial components that seal the gap between the piston and cylinder wall, preventing oil from entering the combustion chamber and controlling blow-by gases. They come in two primary types: compression rings and oil control rings. Compression rings primarily seal combustion pressure, while oil control rings manage oil consumption and reduce friction.

Material Considerations

Modern piston rings are typically made from cast iron, steel, or advanced materials like molybdenum disulfide-coated rings, each offering unique properties such as wear resistance, thermal stability, and friction reduction. The choice of material significantly impacts ring durability and engine performance.

The Importance of Fit in Piston Rings

Dimensional Precision

Achieving the perfect fit for Nissan GA14 piston rings involves precise measurements of both the piston groove and the cylinder wall. Even minor discrepancies can lead to excessive wear, oil consumption, and reduced engine power. Manufacturers use advanced machining techniques to ensure rings fit snugly without causing undue friction.

Radial and Axial Clearance

Radial clearance refers to the space between the ring's outer diameter and the cylinder wall, while axial clearance is the gap between the ring's ends when installed in the piston groove. Proper clearance settings prevent ring binding and ensure smooth operation, critical for maintaining oil control and compression efficiency.

Challenges in Selecting Fit for Nissan GA14

Engine Age and Wear

As engines age, cylinder walls and piston grooves can wear, altering the optimal fit for piston rings. Refurbishing engines often requires selecting rings with slightly different clearances to accommodate this wear, maintaining sealing efficiency.

Fuel Economy and Emissions Regulations

Increasingly stringent fuel economy and emissions regulations necessitate piston rings that minimize blow-by and oil consumption. This requires a balance between tight sealing and low friction, often achieved through advanced materials and coating technologies.

Advanced Techniques for Improving Fit

Laser Processing

Laser texturing of piston ring surfaces enhances oil retention and reduces friction, contributing to better lubrication and longer ring life. This technology allows for extremely precise patterns that optimize oil scraping effectand reduce wear.

Coatings and Surface Treatments

Applying coatings such as diamond-like carbon (DLC) or chromium nitride can significantly improve wear resistance and reduce friction. These treatments are tailored to specific engine operating conditions, ensuring optimal performance over the engine's lifespan.

Case Study: Implementing Improved Piston Rings

Selection Process

When upgrading a Nissan GA14 engine, a thorough analysis of the existing piston ring condition is conducted. Factors such as mileage, maintenance history, and observed performance issues guide the selection of new rings. Manufacturers like Mahle, Federal-Mogul, and DNJ offer a range of options tailored to Nissan engines, incorporating the latest materials and technologies.

Installation and Testing

Professional installation ensures rings are seated correctly and clearances are adjusted according to specifications. Post-installation testing validates improvements in oil consumption, compression efficiency, and overall engine performance.

Conclusion

Choosing the right piston rings for the Nissan GA14 engine is a multifaceted process that combines precise measurements, advanced materials, and cutting-edge manufacturing techniques. By ensuring optimal fit and incorporating the latest technologies, engine efficiency can be significantly enhanced, leading to better fuel economy, reduced emissions, and extended engine life. Understanding the nuances of piston ring selection and fitment is crucial for maintaining the reliability and performance that Nissan engines are renowned for.

https://www.jy-pr.com/choosing-fit-for-nissan-ga14-piston-ring-improving-engine-efficiency.html

www.jy-pr.com

Yizheng Jinyang Locomotive Parts Co., Ltd.