The conductive busbar coating line represents a major step forward in the automation and precision of surface treatment for electrical components. Designed for use in power distribution equipment, transformers, and electrical cabinets, this advanced system ensures optimal performance and longevity of conductive busbars by improving their corrosion resistance, insulation, and mechanical durability. In this blog post, Lexuan Intelligent Equipment, a high quality automatic powder coating equipment exporter, will share the working principle of conductive busbar coating line, its process flow, advantages, applications, etc.

Understanding the Conductive Busbar Coating Line

A conductive busbar coating line is a fully automated coating system engineered to perform precise surface treatment on busbars made of copper or aluminum. These coatings play a critical role in ensuring the safe and efficient transmission of electrical current by preventing oxidation, short circuits, and surface degradation.

The coating process forms a protective layer that enhances electrical insulation, improves moisture and chemical resistance, and delivers a clean, professional finish. As industrial standards demand higher performance and reliability from electrical components, the application of a high-quality coating has become an essential production step.

Core Working Principles of Conductive Busbar Coating Line

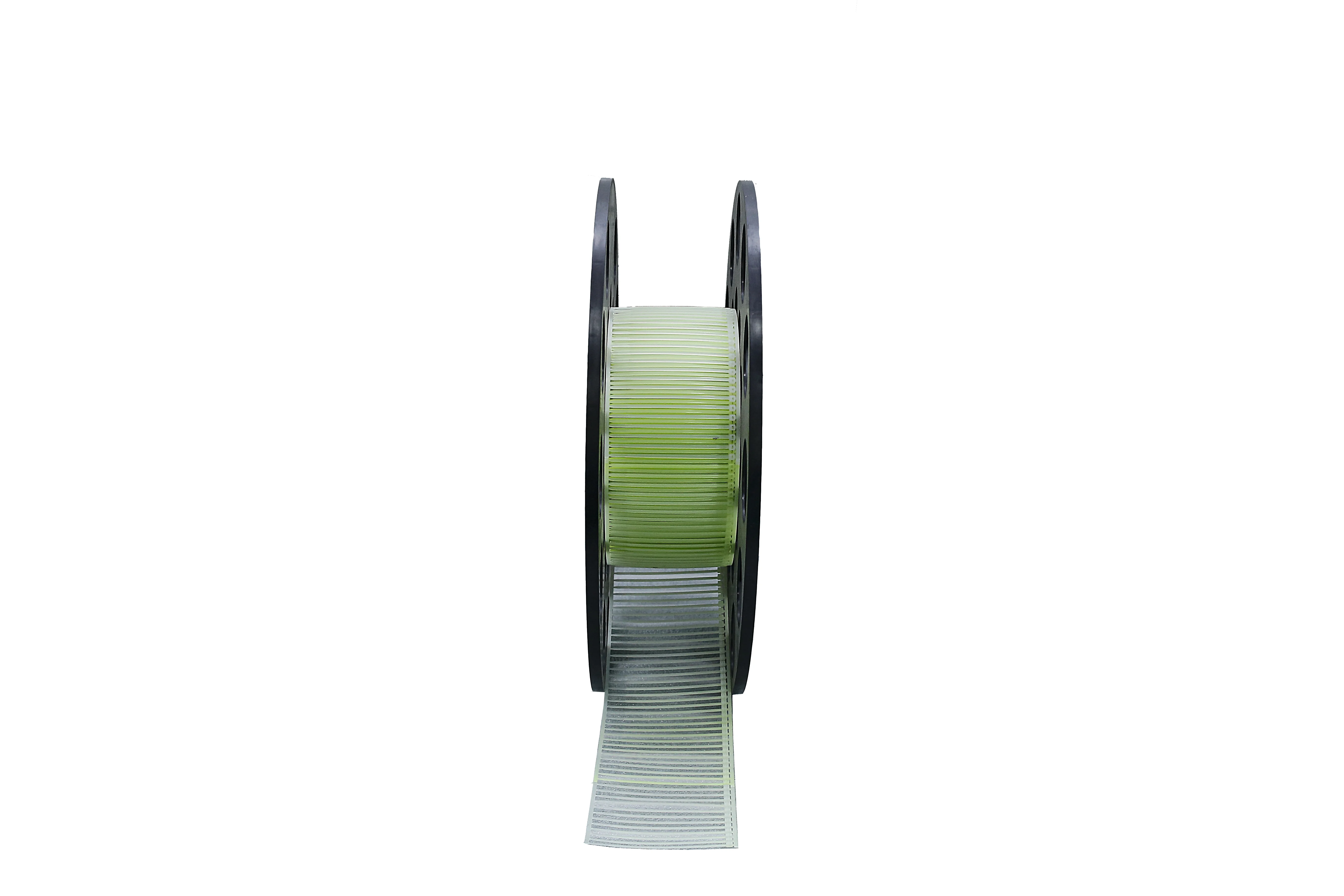

The operating principle of a busbar coating line lies in the application of a uniform powder coating or fluidized bed dipping process. Each method ensures consistent coverage and strong adhesion, even on complex shapes or edges.

-

Powder Coating Process:

In this method, electrostatically charged powder particles are sprayed onto the preheated busbar surface. The powder adheres uniformly and melts to form a continuous film during curing. -

Fluidized Bed Dipping Process:

Smaller busbars are preheated and immersed into a fluidized bed containing fine powder particles. The particles melt and fuse instantly, creating a smooth and thick coating layer.

After coating, the busbars undergo high-temperature curing, which stabilizes the coating and ensures excellent hardness and adhesion. The result is a durable, glossy, and corrosion-resistant surface capable of withstanding demanding electrical and environmental conditions.

Process Flow of Conductive Busbar Coating Line

The technical process flow of a conductive busbar coating line is carefully engineered for precision and repeatability:

-

Preheating:

The busbar is heated to the required temperature to enhance powder melting and adhesion. -

Manual or Automatic Spraying:

Electrostatic powder is evenly sprayed using automated guns or manual systems for special shapes. -

Dipping Coating:

For small-sized parts, dipping ensures full coverage through a controlled fluidized bed process. -

Curing:

The coated busbar is placed in a curing oven where the powder solidifies into a tough, uniform coating layer. -

Cooling:

After curing, the busbar is cooled gradually to maintain coating integrity and prevent thermal stress.

Each stage is precisely controlled by a PLC-based automation system, ensuring repeatability, efficiency, and consistent quality.

Technical Advantages of Conductive Busbar Coating Line

1. High-Efficiency Automated Coating

Automated control systems enable uniform coating thickness, minimize powder waste, and optimize cycle times. With programmable parameters, the line supports continuous production with minimal downtime.

2. Superior Coating Quality and Adhesion

The coating line ensures strong adhesion between the coating and the busbar substrate. The resulting surface demonstrates excellent dielectric strength, resistance to cracking, and durability under electrical stress.

3. Energy-Efficient and Environmentally Friendly

Modern busbar coating lines utilize low-VOC and solvent-free powders, significantly reducing emissions. Energy-saving ovens and recovery systems help lower energy consumption while maintaining stable temperature profiles. This not only reduces operational costs but also complies with environmental regulations.

4. Smart Process Monitoring

Equipped with real-time data collection and monitoring systems, operators can track key parameters such as temperature, coating thickness, and line speed. Intelligent analysis enables predictive maintenance, fault detection, and continuous process optimization.

5. Flexible and Scalable Production Capability

The coating line supports multi-variety and small-batch production, making it ideal for customized busbar designs or projects with varying specifications. Its modular configuration allows for easy upgrades and process adjustments according to production demands.

6. Enhanced Durability and Product Longevity

The resulting coating provides superior corrosion, wear, and moisture resistance, extending the service life of busbars in both indoor and outdoor installations. The combination of mechanical robustness and chemical stability ensures reliable electrical performance over time.

Industrial Applications of Busbar Coating Line

The conductive busbar coating system is widely used in sectors that demand high electrical performance and reliability:

-

Power Distribution Systems: Protecting copper and aluminum busbars from oxidation and short circuits.

-

Electrical Cabinets and Switchgear: Improving insulation and visual aesthetics in compact installations.

-

Transformers and Power Modules: Providing enhanced corrosion and heat resistance.

-

Renewable Energy Equipment: Used in solar inverters and wind turbine control panels.

-

Industrial Automation Systems: Ensuring consistent conductivity in machinery and control units.

Its versatility makes it suitable for large-scale manufacturing as well as precision electrical applications where reliability is critical.

Future Outlook of Conductive Busbar Coating Technology

With the rapid expansion of renewable energy, electric vehicles, and smart grid infrastructure, the demand for high-quality conductive busbars continues to grow. Future developments in coating lines are expected to focus on:

-

Integration of AI and machine learning for predictive process control.

-

Advanced powder formulations with improved dielectric strength.

-

Automation upgrades for faster color changes and material handling.

-

Sustainable manufacturing with recyclable and eco-friendly coating materials.

These advancements will further elevate the efficiency, precision, and sustainability of busbar coating operations worldwide.

Conclusion

The conductive busbar coating line is more than a surface treatment solution—it is a comprehensive production system that ensures safety, efficiency, and durability in electrical engineering applications. By integrating automated technology, energy-efficient processes, and smart monitoring, manufacturers can achieve superior coating performance while meeting global environmental standards.

As electrical systems evolve toward higher performance and sustainability, investing in a modern busbar coating line becomes an essential step for manufacturers seeking long-term reliability and competitive advantage in the power industry.

www.lexuaneqpt.com

Lexuan Intelligent Equipment