Role of Double Head Solar Panel Cleaning Brush in PV System Care

As solar energy becomes an essential part of global power generation, maintaining the efficiency of photovoltaic (PV) panels is critical. The double head solar panel cleaning brush has emerged as a professional tool for ensuring consistent panel performance. Designed for large-scale installations and difficult-to-reach panels, this cleaning system offers a combination of mechanical precision and ergonomic operation that optimizes maintenance efficiency.

The accumulation of dust, pollen, bird droppings, and environmental residues can significantly reduce solar power output. A well-designed double brush cleaning system ensures comprehensive coverage, gentle cleaning, and minimal water consumption—all key to sustaining long-term solar efficiency. In this blog post, WANLV, a high quality solar panel washing brush manufacturer, will share the benefits of double head solar panel cleaning brush for efficient photovoltaic maintenance.

Structure and Function of Double Brush Solar Cleaning System

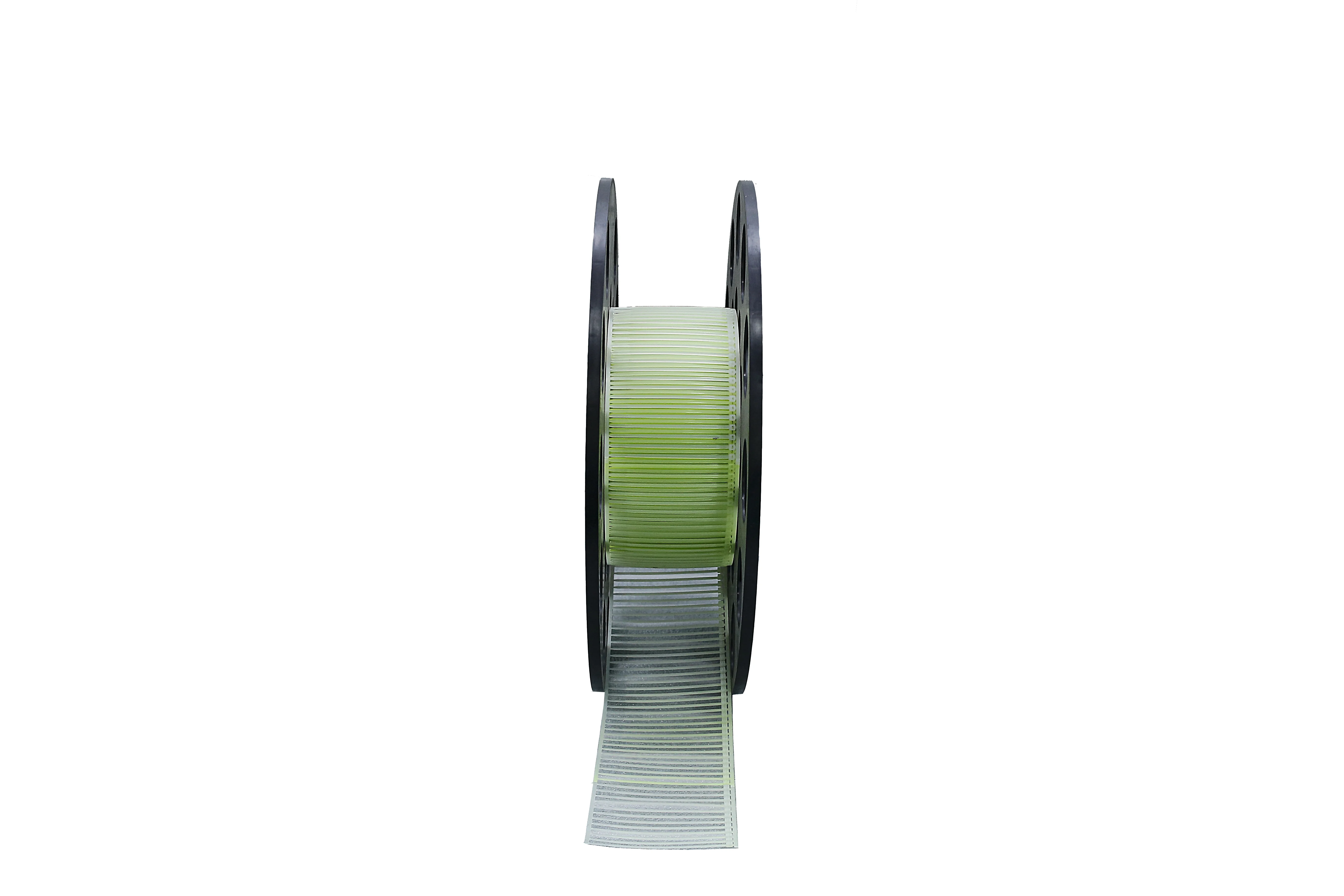

A double head solar panel cleaning brush typically features two rotating brush heads driven by a motorized unit, powered either by electricity or water flow. The dual-brush configuration increases cleaning area and contact pressure balance, allowing for thorough removal of dirt without scratching the surface.

Each brush head often uses soft nylon or carbon fiber bristles that adapt to the delicate glass surface of solar panels. The heads rotate in opposite directions, reducing friction resistance while maintaining stable cleaning pressure. This coordinated motion ensures even cleaning results and prevents streaking—especially important for high-output PV arrays where optical clarity directly affects energy conversion.

Automatic and Manual Options for Double Head Solar Cleaning Brushes

There are two main types of double head solar panel cleaning brushes:

-

Manual telescopic models – These are ideal for small or medium-scale rooftop installations. Operators can adjust the handle length and brush angle, reaching panels efficiently without stepping on them.

-

Automatic water-fed systems – Equipped with a water inlet and motorized rotation, these models are suitable for ground-mounted or industrial-scale solar farms. The combination of pressurized water and rotating dual brushes ensures quick, uniform cleaning with reduced labor effort.

In both configurations, the focus remains on maximizing panel performance while minimizing maintenance time and cost. The choice between manual and automated systems depends on panel layout, terrain, and cleaning frequency.

Advantages of Using Double Head Solar Panel Cleaning Brush

A dual head solar brush offers several operational and performance advantages over traditional single-head or manual wiping methods:

-

Increased cleaning efficiency: Two brushes work simultaneously, covering a wider area in one pass and reducing cleaning time by up to 40%.

-

Gentle surface contact: The soft bristle design ensures that delicate solar glass surfaces remain unscratched, maintaining transparency and panel integrity.

-

Water-saving mechanism: Many advanced models integrate a water-fed tube system that releases a controlled flow, reducing water waste while softening dirt for easier removal.

-

Adaptability: The brush system can be adjusted for panel tilt angles and array spacing, ensuring suitability across diverse installation types—from residential rooftops to desert-based solar farms.

-

Durability and maintenance simplicity: The robust mechanical design and corrosion-resistant materials ensure long service life even under intense sunlight and varying weather conditions.

Optimizing Solar Output Through Regular Double Brush Cleaning

Research and field tests have shown that dirty panels can lose 15–25% of their power output. Regular cleaning with a double brush solar panel cleaner restores efficiency by removing debris that blocks sunlight and disrupts electrical performance.

For regions with high dust levels—such as deserts or agricultural zones—weekly or biweekly cleaning may be necessary. In contrast, temperate or urban areas may require less frequent cleaning. By incorporating automated double brush systems, solar farm operators can maintain a consistent maintenance schedule that optimizes return on investment (ROI) and prolongs module lifespan.

Integration of Double Head Solar Cleaning Brushes with Smart Maintenance Systems

The future of solar maintenance lies in automation and data-driven control. Modern double head solar panel cleaners are being integrated into robotic cleaning systems that use sensors, GPS positioning, and AI-based route planning. These smart systems detect dirt accumulation, schedule automatic cleaning cycles, and track efficiency improvements in real time.

Such integration reduces human labor, minimizes operational downtime, and ensures optimal energy generation across vast solar farms. The modular design of dual-brush systems also makes them easy to retrofit into existing maintenance robots.

Sustainability Impact of Dual Brush Cleaning Systems

In addition to performance gains, double head solar panel cleaning systems contribute to environmental sustainability. Their efficient water use and reduced chemical dependency align with the eco-friendly principles of renewable energy. Many water-fed brush systems now incorporate recycling filters to reuse cleaning water, further minimizing environmental impact.

By maintaining cleaner panels and improving energy capture, these brushes indirectly reduce the carbon footprint per unit of generated electricity—supporting the broader mission of clean energy development.

Choosing the Right Double Head Solar Panel Brush for Your Application

When selecting a double head solar panel cleaning brush, consider the following factors:

-

Panel configuration: Roof-mounted vs. ground-mounted systems require different handle lengths or automation capabilities.

-

Water availability: Choose between dry and water-fed options based on local conditions.

-

Material compatibility: Ensure that brush bristles are soft enough for tempered solar glass.

-

Operational scale: Manual brushes suit smaller installations, while large-scale farms benefit from automated dual brush robots.

Manufacturers are continually innovating in this field, offering lightweight carbon-fiber handles, foldable brush arms, and energy-efficient motors that make solar maintenance more accessible and sustainable.

Conclusion

The double head solar panel cleaning brush represents more than just a maintenance tool—it’s a key element in maximizing the long-term efficiency and sustainability of solar energy systems. By combining mechanical precision, environmental responsibility, and automation readiness, the double brush design ensures that every panel operates at its highest potential.

As global solar capacity continues to expand, reliable and efficient cleaning technologies will remain central to maintaining productivity. The double head brush stands out as a smart, scalable solution—bridging the gap between manual cleaning and intelligent maintenance for a brighter, cleaner energy future.

www.wlsolarcleaning.com

WANLV