Have you ever wondered what keeps complex electronic systems safe from heat, electricity, and environmental stress? FR4 insulation board is the backbone of modern electronics, offering strength, stability, and high dielectric performance. It plays a vital role in ensuring reliability in circuits and industrial devices. Understanding its properties and uses can help you choose the right insulation solution for your project.

What Is an FR4 Insulation Board

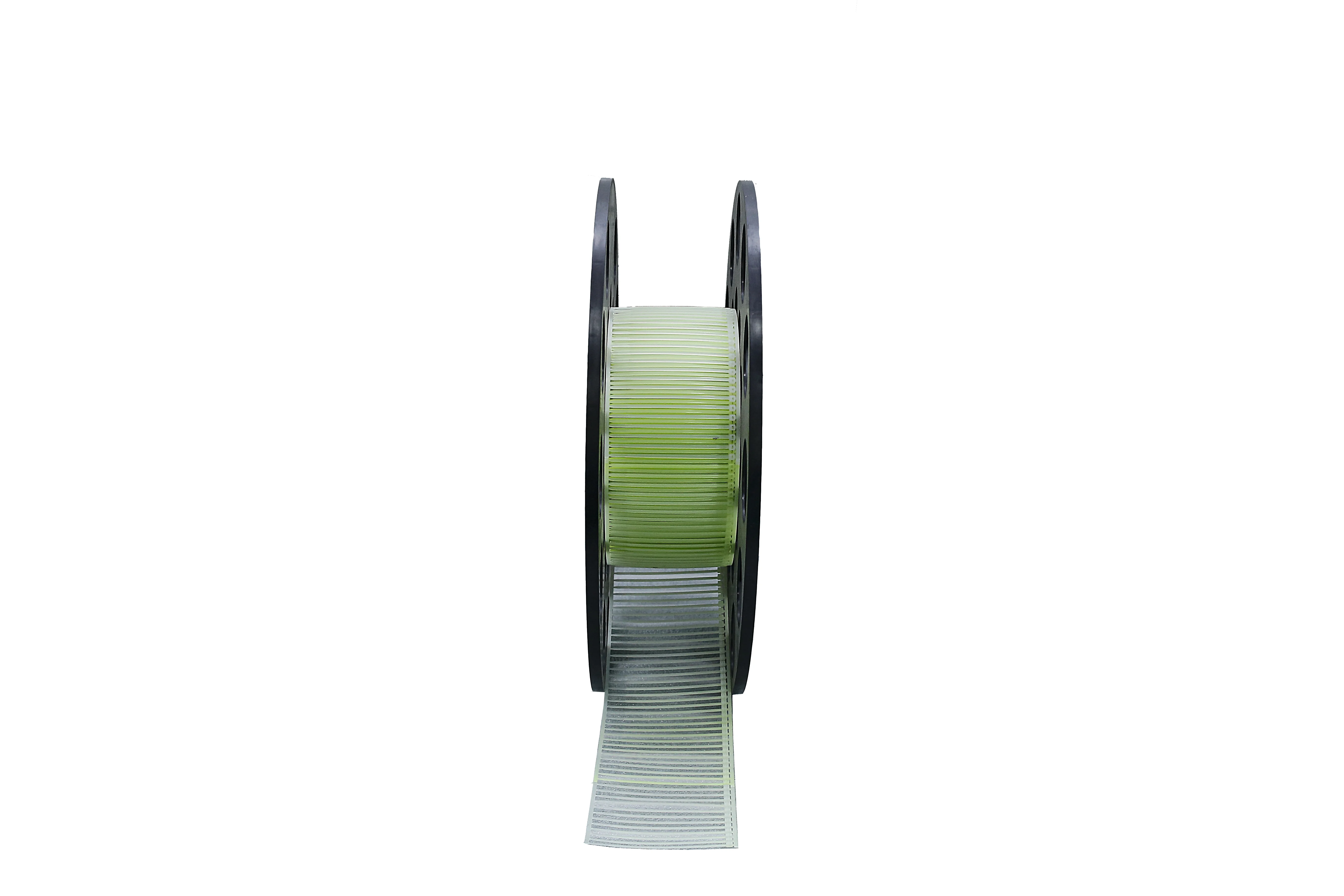

An FR4 insulation board is a composite material made of woven fiberglass cloth and epoxy resin. The “FR” stands for flame retardant, indicating that the material can withstand high temperatures without burning. This feature makes it ideal for electronic and industrial applications that require both strength and safety.

The board provides excellent electrical insulation and mechanical stability, ensuring that delicate electronic components operate safely even in demanding environments. Its strong resistance to heat, moisture, and chemicals has made FR4 the standard substrate for printed circuit boards (PCBs) and other electronic insulation applications.

Key Advantages of FR4 Insulation Boards

FR4 insulation boards offer a combination of physical strength, lightweight structure, and electrical performance. Some of their key advantages include:

-

High dielectric strength: Ensures stable electrical insulation between circuits.

-

Excellent mechanical stability: Retains rigidity and form even under pressure.

-

Thermal resistance: Withstands high operational temperatures.

-

Moisture and chemical resistance: Protects electronics from corrosion and damage.

-

Easy machining: Can be drilled, cut, or shaped for customized components.

These properties make FR4 insulation boards suitable for applications that demand both mechanical durability and electrical reliability.

Applications of FR4 Insulation Boards in Modern Industry

FR4 insulation boards are widely used in several industries, including electronics, automotive, and power systems.

-

Printed Circuit Boards (PCBs): FR4 is the most commonly used base material for multilayer PCBs due to its excellent electrical insulation and mechanical strength.

-

Electrical Equipment: Used in transformers, switchgear, and control cabinets to separate live parts safely.

-

Industrial Automation: Serves as structural insulation in robots, control panels, and communication systems.

-

Aerospace and Defense: Offers lightweight and flame-retardant protection for electronic systems.

The versatility of FR4 boards also extends to renewable energy devices, such as wind turbines and solar inverters, where insulation and heat resistance are essential for consistent performance.

Choosing the Right FR4 Insulation Board

Selecting the right FR4 insulation board depends on application requirements such as thermal resistance, thickness, and dielectric strength. For high-power or high-frequency systems, boards with low dielectric loss and higher Tg (glass transition temperature) are preferred.

When ordering in bulk, manufacturers often provide options for custom thickness, size, and surface finish to match your specific project needs. In precision applications, even slight differences in board thickness can impact the overall efficiency and reliability of the device.

If your system operates in a high-temperature or high-moisture environment, always choose FR4 boards with enhanced thermal and chemical resistance. These upgrades ensure longer operational life and better performance stability.

The Role of FR4 Insulation Boards in Electronic Reliability

In the electronics industry, consistency and reliability are everything. FR4 insulation boards ensure consistent circuit performance by minimizing the risk of electrical leakage, overheating, and short circuits.

Their high mechanical stability prevents warping, ensuring that circuits remain aligned and solder joints stay intact over time. The flame-retardant nature of FR4 also provides a safety advantage, protecting components from heat damage and reducing fire risks.

Moreover, FR4’s versatility makes it ideal for multi-layer board configurations, supporting both rigid and flexible designs. This allows engineers to build complex electronic assemblies while maintaining compactness and efficiency.

Why Choose Jiecheng Electronic Materials for FR4 Insulation Boards

When sourcing high-quality FR4 insulation boards, Jiecheng Electronic Materials stands out as a trusted supplier with strong technical expertise. As a wholly-owned subsidiary of Shenzhen Xiongyihua Insulation Materials Group, Jiecheng benefits from decades of material science experience and patented technologies.

Technical Expertise and Advanced Facilities

Jiecheng operates a 10,000㎡ smart production base with over 60 precision CNC machines, ensuring accuracy and consistency in every product. With ISO 9001 and ISO 14001 certifications, Jiecheng guarantees quality control and environmental responsibility at every stage.

Innovative Material Solutions

The company extends its parent group’s expertise in FR4 fiberglass technology to produce ultra-thin electronic-grade insulation boards ranging from 0.15mm to 3.0mm. These boards are ideal for high-density circuit assemblies, 5G communication equipment, and power management systems.

Customization and Global Service

Jiecheng provides customized insulation boards tailored to each client’s requirements—whether for small prototypes or large industrial orders. Their global customer service ensures timely delivery, technical support, and long-term partnership reliability.

FR4 Insulation Board and the Future of Electronics

As electronics become smaller, faster, and more powerful, insulation materials like FR4 play a vital role in supporting these advancements. The demand for thinner, more heat-resistant, and higher-performance FR4 insulation boards continues to grow.

Manufacturers are now combining FR4 with other advanced composites to enhance mechanical and electrical properties further. These innovations ensure that FR4 remains a key material in next-generation circuit design and industrial applications.

Conclusion: Partner with Jiecheng for Trusted FR4 Insulation Solutions

FR4 insulation boards are essential to the reliability and safety of modern electronic systems. From industrial automation to advanced communication devices, they offer consistent performance and protection.

By choosing Jiecheng Electronic Materials, you gain access to premium FR4 insulation boards backed by patented technology, modern production facilities, and expert technical support.

Contact Jiecheng today to discuss your project needs and experience high-quality insulation materials designed for long-term success.

https://www.jc-insulant.com/fr4-epoxy-fiberglass-sheet.html

Jiecheng