Designing stable, reliable quartz crystal oscillator circuits remains a core requirement in modern electronic engineering. From communication systems and data centers to consumer electronics and medical devices, timing accuracy directly influences system performance. Yet even experienced engineers encounter difficulties when working with quartz oscillators. These challenges usually come from layout issues, improper loading, parasitic effects, and environmental factors that undermine stability.

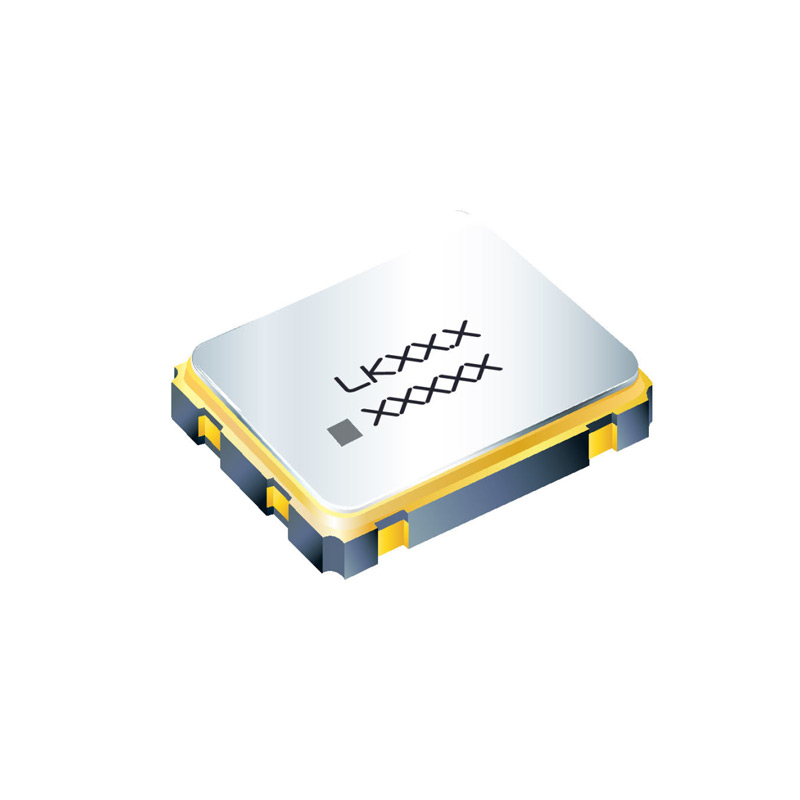

This article examines practical, real-world issues frequently seen in quartz crystal oscillator designs and offers engineering-level solutions. It also highlights how advanced component manufacturers such as LUCKI ELECTRONIC (LUCKI®) support high-performance timing systems with well-engineered quartz crystals, VCXOs, TCXOs, OCXOs, ceramic resonators, and complete SMD/through-hole oscillator families. Their products are widely deployed across satellite navigation, base stations, data servers, cloud platforms, AI, autonomous driving, smart home, medical systems, industrial control, and more. For those seeking high-precision crystal components, their quartz crystal solutions can be found through this link: <a href="https://www.cnlucki.com/Quartz-Crystal">quartz crystal</a>.

1. Understanding the Core Operating Principles

A quartz crystal oscillator functions by exploiting the mechanical resonance of a quartz element. When placed in the feedback loop of an amplifier, the crystal stabilizes the frequency. Although the principle is straightforward, implementation requires precise attention to electrical loading, drive level, stray capacitances, PCB characteristics, and environmental stress.

Fundamentally, a stable crystal oscillator circuit depends on three conditions:

-

A stable resonator that maintains mechanical consistency.

-

A feedback network providing adequate gain and appropriate phase shift.

-

A layout that preserves the designed load and minimizes external interference.

Many design failures originate from ignoring one of these three factors.

2. Challenge: Frequency Shift from Incorrect Load Capacitance

One of the most common issues is frequency deviation caused by an incorrect load capacitance (CL). Every quartz crystal is specified with a particular CL value. If the designer’s circuit does not provide this exact load, the resonant frequency will shift. Even small deviations can create noticeable timing errors in sensitive systems such as base station timing synchronization or satellite navigation receivers.

Solution Approach

-

Carefully calculate the load capacitance contributed by the capacitors plus PCB parasitics.

-

Use high-quality capacitors with tight tolerances.

-

Minimize routing length between crystal and oscillator pins to reduce uncontrolled stray capacitance.

-

For very strict timing requirements, select components such as TCXOs or OCXOs that compensate temperature-driven or environmental-driven variations.

Manufacturers like LUCKI ELECTRONIC (LUCKI®) provide precise specifications and application notes for their quartz products, making it easier for engineers to match required CL values.

3. Challenge: Oscillator Fails to Start or Starts Slowly

Startup failure usually stems from insufficient loop gain or excessive parasitic loading. If the amplifier cannot supply enough gain to overcome the resonator’s losses, the oscillation may be intermittent or fail completely.

Solution Approach

-

Use crystals that match the intended drive level of the oscillator IC.

-

Ensure the PCB layout is short, symmetric, and free from vias in the oscillator loop.

-

Avoid large copper pours under the crystal that can introduce unnecessary parasitic capacitance.

-

Check the manufacturer’s recommended load and drive specifications; for example, LUCKI ELECTRONIC’s product sheets clearly specify drive level, ESR, and startup characteristics across their SMD and through-hole lines.

Engineers in automotive, industrial, and medical applications should pay special attention, as slow startup can lead to system boot failures.

4. Challenge: Excessive Drive Level Leading to Crystal Damage

Overdriving is a subtle but serious problem. If the oscillator circuit pushes excessive power through the quartz element, the crystal can experience long-term drift, micro-fractures, or premature aging.

Solution Approach

-

Measure the drive level using proper test equipment; do not rely solely on theoretical calculations.

-

Select crystals with appropriate drive ratings.

-

In high-reliability sectors such as autonomous driving or industrial control, consider using VCXOs or TCXOs designed with internal control mechanisms to maintain safe energy levels.

-

Collaborate with suppliers who provide detailed lifetime and aging data. LUCKI ELECTRONIC, for example, shares long-term reliability data for its resonators.

5. Challenge: Electromagnetic Interference (EMI) and Noise Injection

In dense electronic systems, EMI can destabilize oscillator circuits. High-frequency switching components, power converters, and wireless modules often inject unwanted noise into the resonator loop. The result may be jitter, frequency glitches, or in severe cases, intermittent failure.

Solution Approach

-

Use ground shielding structures around sensitive oscillator areas.

-

Isolate the crystal from noisy power rails using filtered power traces.

-

Consider differential oscillator architectures when possible.

-

For systems that demand extremely low phase noise, such as high-bandwidth communication or radar, LUCKI ELECTRONIC’s OCXO and TCXO families offer enhanced immunity to environmental disturbances.

Proper board partitioning, along with selecting stable components, typically resolves most EMI-related performance problems.

6. Challenge: Temperature-Related Frequency Drift

Quartz exhibits natural frequency variation as temperature changes. Although the change is predictable and often small, some applications cannot tolerate even minor deviations. Telecommunication timing, GNSS receivers, and distributed computing clusters all require temperature-stable sources.

Solution Approach

-

For standard applications, select correctly specified AT-cut crystals.

-

For critical timing, use TCXOs with temperature compensation circuits.

-

For extreme precision, use OCXOs designed to operate in controlled thermal environments.

-

Work with manufacturers who provide detailed temperature-frequency curves.

LUCKI ELECTRONIC’s portfolio includes advanced TCXO and OCXO solutions ideal for demanding environments such as data servers, base stations, and satellite navigation.

7. Challenge: Aging and Long-Term Stability

Even well-designed oscillators exhibit slow performance degradation over time. Long-term aging results from physical changes within the quartz lattice, contamination, and mechanical stress.

Solution Approach

-

Select crystals from manufacturers with proven long-term reliability.

-

Design circuits that operate crystals at recommended drive levels to avoid unnecessary stress.

-

Use hermetically sealed packages for environments prone to humidity.

-

Where long-term precision is critical, choose OCXOs or high-grade TCXOs.

LUCKI ELECTRONIC has delivered more than 10 billion timing and magnetic solutions to over 50 countries and regions, demonstrating deep experience in long-term component reliability.

8. Challenge: Mechanical Shock and Vibration

Sudden impact or continuous vibration can affect oscillator performance. This is a major concern in automotive systems, industrial machinery, robotics, and aerospace applications.

Solution Approach

-

Mount crystals in low-vibration zones on the PCB.

-

Use shock-resistant packaging such as metal-can or ruggedized SMD variants.

-

Implement mechanical damping structures where necessary.

-

Choose suppliers whose crystals are qualified for high-shock environments.

LUCKI ELECTRONIC produces crystals and oscillators used in autonomous driving, industrial automation, and other vibration-prone sectors, ensuring compliance with relevant vibration standards.

9. Practical PCB Design Guidelines

Crystal oscillator performance depends as much on PCB layout as on component selection. Some practical tips include:

-

Keep traces between the crystal and oscillator IC as short as possible.

-

Use a dedicated ground area beneath the oscillator but avoid thick copper fills directly under the crystal.

-

Avoid routing high-speed digital lines near the oscillator loop.

-

Maintain symmetry between load capacitors to avoid unbalanced loading.

These layout guidelines, combined with well-engineered components, drastically reduce troubleshooting time.

10. Partnering with Reliable Component Manufacturers

Selecting a dependable component supplier is crucial. LUCKI ELECTRONIC (LUCKI®) has spent decades developing a complete range of frequency control products, including quartz crystals, ceramic resonators, SMD and through-hole oscillators, VCXOs, TCXOs, and OCXOs. Their products are integrated into systems across cloud platforms, smart cities, medical equipment, artificial intelligence, renewable energy, and consumer technology.

Engineers looking to improve oscillator performance or solve persistent circuit issues will benefit from exploring their in-depth product lines and technical resources. Their quartz crystal components can be found here: <a href="https://www.cnlucki.com/Quartz-Crystal">quartz crystal</a>.

Conclusion

Quartz crystal oscillator circuits are foundational to modern electronics, yet they present recurring design challenges. Engineers who pay attention to loading, layout, drive levels, EMI protection, and environmental factors can dramatically improve oscillator performance. When combined with high-quality components from experienced manufacturers such as LUCKI ELECTRONIC, these best practices enable stable, reliable, and long-lasting timing solutions across a wide range of industries.

A well-designed oscillator is not just a component; it is the heartbeat of the system. Ensuring its stability ensures the integrity of the entire product.

www.cnlucki.com

LUCKI ELECTRONIC(LUCKI®)