In an era where electric vehicles, renewable energy, aerospace systems, and smart manufacturing drive global progress, high-performance cabling is more critical than ever. These industries often operate in harsh environments—exposed to heat, pressure, and chemical stress—where traditional PVC or PE cables quickly degrade.

This is where silicone wire and cable extrusion machines play an irreplaceable role. Designed to produce flexible, heat-resistant, and durable cables, they enable manufacturers to meet the stringent demands of modern high-temperature applications.

Since its founding in 1998, Jinghan Machinery (Dongguan) Co., Ltd. has been at the forefront of cable production technology. Combining advanced Taiwanese engineering with local R&D and manufacturing expertise, Jinghan has become a trusted supplier of high-end, precision cable machinery worldwide.

This article explores how silicone wire and cable extrusion machines work, why silicone cables are vital for high-temperature performance, and how Jinghan’s innovation is shaping the future of cable manufacturing.

Understanding High-Temperature Cable Applications

High-temperature environments are common in industrial, automotive, and aerospace operations. From electric motors and engine compartments to solar farms and high-voltage systems, cables must perform reliably despite extreme heat.

Typical high-temperature applications include:

-

Automotive: Engine wiring harnesses and EV charging systems

-

Aerospace: Avionics, sensors, and propulsion systems

-

Renewable energy: Solar photovoltaic and wind turbine cables

-

Industrial automation: Robotics, furnaces, and heavy-duty motors

-

Medical and electronics: Sterilizable or precision instrument wiring

In all these sectors, silicone cables excel due to their exceptional thermal endurance, flexibility, and electrical stability.

Why Silicone Is the Ideal Material

Silicone rubber’s chemical structure gives it superior stability under heat. It maintains flexibility and insulation properties from -60°C up to +250°C, making it ideal for both cold and hot environments.

Key advantages of silicone insulation include:

-

Outstanding Thermal Resistance – Unlike thermoplastics, silicone does not soften or melt easily under high temperatures.

-

Excellent Electrical Properties – It provides consistent dielectric strength and insulation even when exposed to voltage stress.

-

Superior Flexibility – Retains elasticity in both extreme heat and sub-zero temperatures.

-

Chemical and Weather Resistance – Withstands oil, ozone, and UV radiation, ensuring durability outdoors or in industrial settings.

-

Flame Retardancy – Generates low smoke and minimal toxic gases when exposed to flame.

These attributes make silicone cables indispensable for modern engineering systems that operate under demanding thermal conditions.

The Role of Silicone Wire and Cable Extrusion Machines

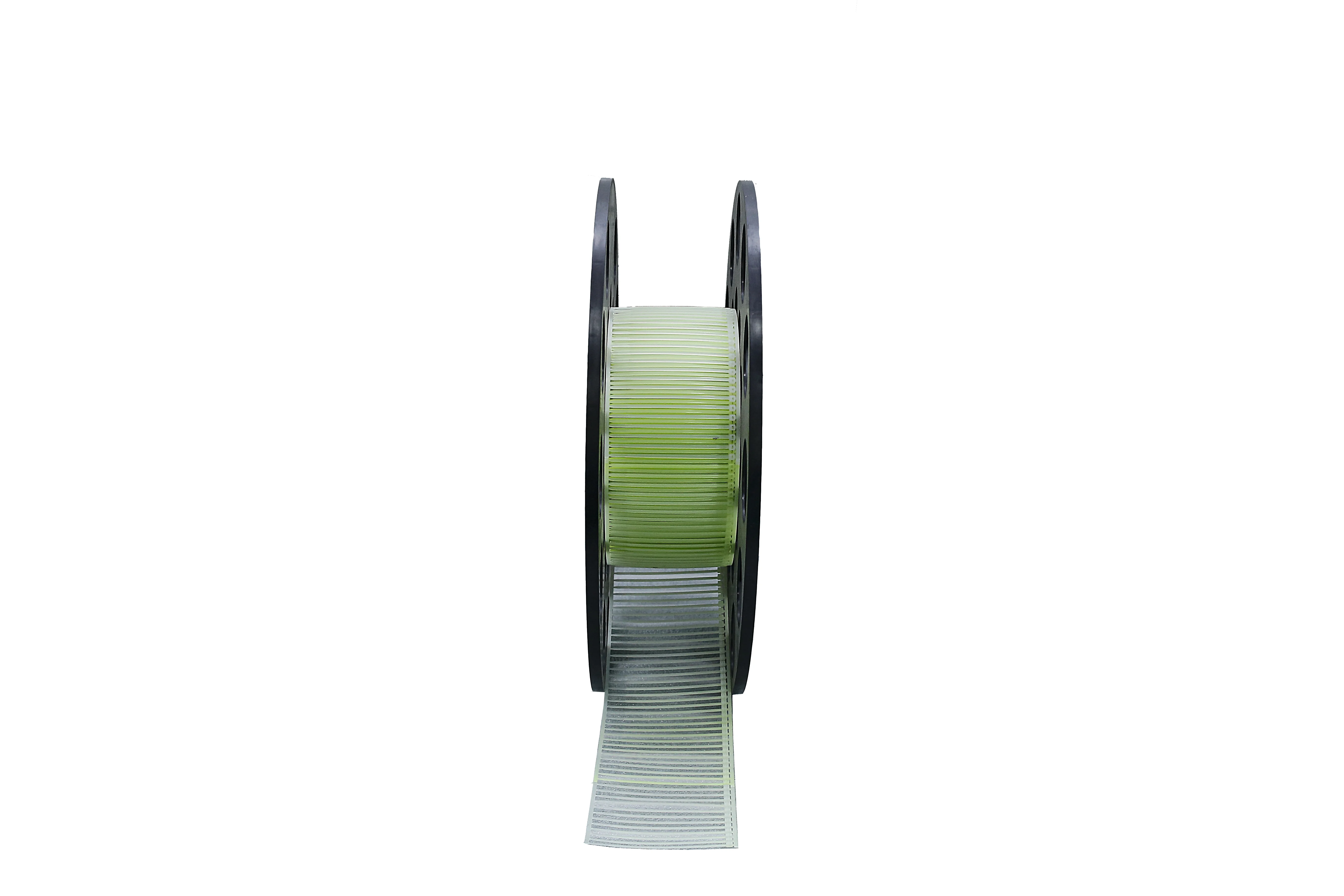

Producing silicone cables with consistent quality requires specialized extrusion technology. A Silicone Wire and Cable Extrusion Machine ensures that the silicone compound is melted, mixed, and applied evenly over the conductor, forming a seamless insulation layer.

The Silicone Wire and Cable Extrusion Machine from Jinghan Machinery represents one of the most advanced systems available today. Its precise control mechanisms and smart automation guarantee uniform cable geometry, high throughput, and minimal material waste—all essential for high-temperature cable production.

Let’s look at the specific reasons why these machines are so critical for high-performance manufacturing.

1. Precise Temperature and Pressure Control

In silicone extrusion, the slightest variation in temperature or pressure can compromise insulation integrity. Overheating can cause scorching or molecular breakdown, while underheating results in poor curing.

Modern extrusion machines from Jinghan use multi-zone PID temperature control systems that ensure stable heat distribution throughout the screw barrel and die head. Real-time monitoring adjusts conditions instantly, maintaining uniform compound viscosity and density.

This level of control ensures that every meter of cable meets the same quality standards—critical for industries like aerospace and automotive, where reliability is non-negotiable.

2. Uniform Insulation Thickness and Superior Surface Quality

Consistency in insulation thickness is essential for maintaining dielectric strength and minimizing electrical loss. Advanced extrusion technology provides accurate material flow and pressure control, resulting in smooth, concentric coatings.

Jinghan’s silicone wire extrusion systems integrate closed-loop diameter control and high-precision screw design, ensuring consistent wall thickness and superior surface finish.

This precision directly enhances cable longevity and performance under thermal stress.

3. Enhanced Production Efficiency

High-temperature cables are often complex to produce, but automated extrusion systems dramatically improve efficiency.

Jinghan’s equipment features:

-

PLC-based control systems for centralized management

-

Synchronized take-up and pay-off mechanisms

-

Real-time data monitoring for process optimization

Automation reduces operator dependency, shortens setup time, and enables continuous production at stable speeds. The result is higher throughput with reduced energy consumption and material waste.

For manufacturers aiming to scale production while maintaining precision, these systems deliver both speed and stability.

4. Extended Material Life and Energy Savings

Energy efficiency is no longer optional—it’s a necessity for modern factories. Silicone extrusion machines from Jinghan are engineered for energy-saving operation, featuring variable frequency drives (VFDs), efficient heating systems, and optimized cooling circuits.

Uniform processing conditions reduce thermal stress on materials, ensuring optimal cross-linking and longer cable life. In addition, consistent temperature control minimizes start-up scrap, improving overall material utilization and sustainability.

5. Reliability in Extreme Operating Environments

Silicone cables must withstand not only heat but also mechanical vibration, chemicals, and environmental exposure. Machines designed specifically for silicone extrusion, such as Jinghan’s, are built to handle these challenges with unmatched consistency.

Features like wear-resistant screw barrels, corrosion-proof dies, and robust frame construction guarantee stable performance over long production runs. These qualities ensure that the cables produced remain dependable across thousands of hours of service.

Case Example: Meeting Demands of the Automotive and Aerospace Sectors

In electric vehicles (EVs), under-hood wiring must endure temperatures exceeding 150°C for extended periods. Similarly, aerospace cables must perform flawlessly under rapid temperature fluctuations and mechanical vibration.

Jinghan’s silicone wire extrusion lines help manufacturers in these sectors produce cables that meet international standards such as UL, ISO, and SAE, ensuring both safety and reliability.

By combining intelligent control with mechanical precision, these systems enable consistent mass production of high-quality cables for mission-critical environments.

How Jinghan Machinery Leads in Silicone Extrusion Technology

Founded in 1998, Jinghan Machinery (Dongguan) Co., Ltd. has spent over two decades perfecting cable production systems. Rooted in Taiwanese engineering heritage, the company has built a reputation for technology leadership and innovation.

Key strengths include:

-

Dozens of national patents covering extruders, stranders, and cablers.

-

High-performance manufacturing systems designed for energy efficiency.

-

Comprehensive R&D to improve automation, precision, and sustainability.

-

Global reach, with customers in Asia, Europe, and beyond.

Jinghan’s Silicone Wire and Cable Extrusion Machine is a testament to this expertise—combining precision engineering, smart control, and reliable performance to help manufacturers achieve excellence in high-temperature cable production.

The Future of High-Temperature Cable Manufacturing

As industries continue to innovate, demand for heat-resistant, lightweight, and eco-friendly cables will only increase. Future silicone extrusion lines are expected to integrate:

-

AI-driven process optimization for predictive control

-

IoT-enabled data collection for real-time quality analysis

-

Digital twin simulations for process validation and operator training

-

Eco-efficient heating systems to reduce carbon emissions

Jinghan Machinery is actively developing these next-generation technologies, ensuring its customers stay ahead in an evolving manufacturing landscape.

Conclusion

High-temperature environments demand cables that combine durability, flexibility, and safety. Producing such cables with precision and efficiency requires the right technology—one that only specialized silicone wire and cable extrusion machines can deliver.

From precise temperature control and automation to energy efficiency and material optimization, these systems are the backbone of advanced cable production.

With its strong foundation in Taiwanese technical expertise, continuous innovation, and decades of manufacturing experience, Jinghan Machinery (Dongguan) Co., Ltd. continues to lead the global market in extrusion solutions.

For manufacturers seeking reliable, high-performance equipment, Jinghan’s Silicone Wire and Cable Extrusion Machine offers the perfect balance of precision, productivity, and long-term value.

To explore the full range of technical specifications and applications, visit:

Silicone Wire and Cable Extrusion Machine – Jinghan Machinery

www.jinhanmachinery.com

Jinghan Machinery (Dongguan) Co., Ltd.