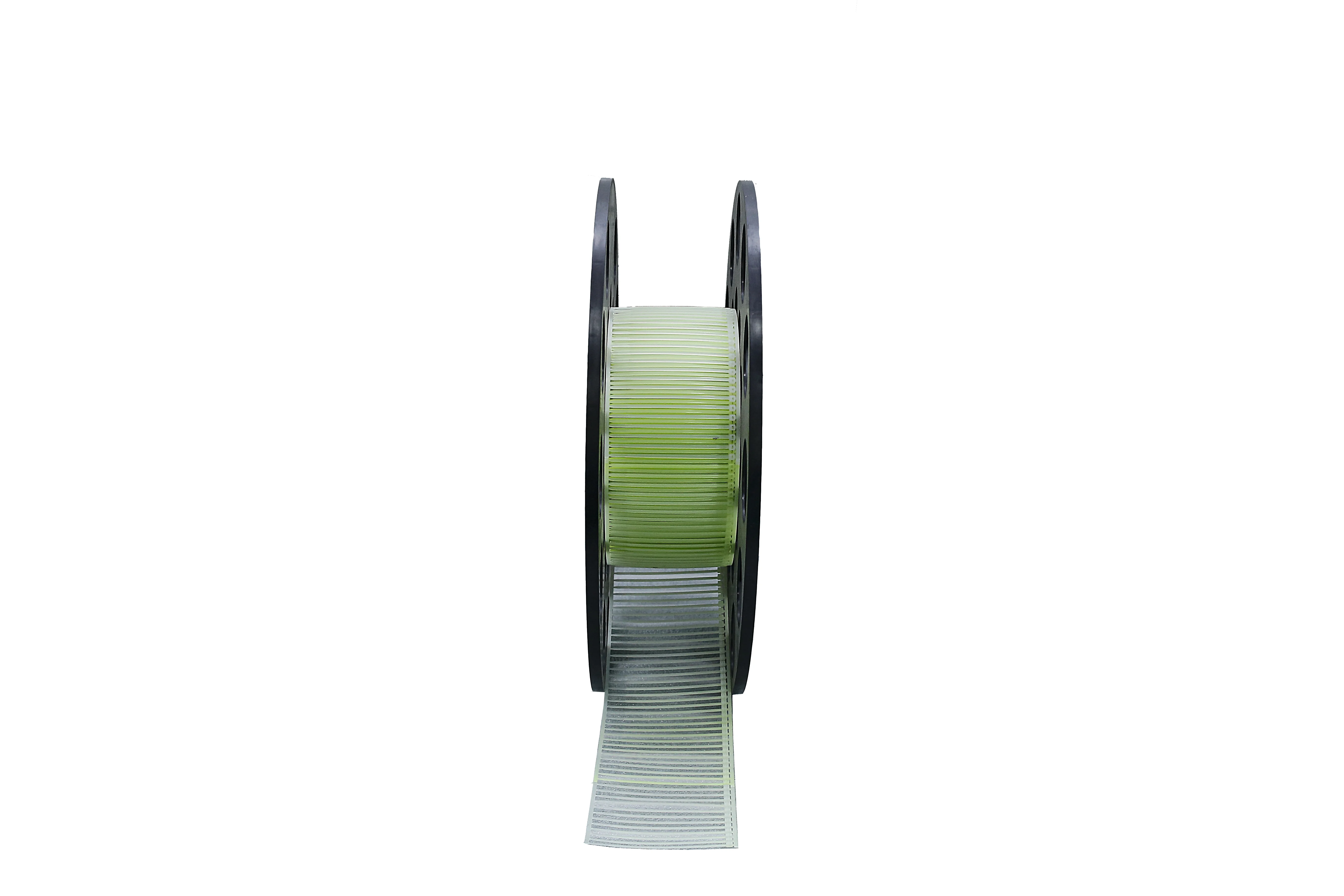

As the demand for high-efficiency, compact, and high-speed electric motors continues to grow across industries such as automotive, automation, and renewable energy, selecting the right rotor structure has become increasingly crucial. Among the many rotor technologies available, the Steel Shaft Magnetic Rotor has emerged as a preferred choice thanks to its outstanding mechanical and magnetic properties.

Here are five major advantages of using steel shaft magnetic rotors in modern motor systems:

1. Superior Mechanical Strength and Stability

The steel shaft serves as the structural core of the rotor, offering excellent resistance to torsional stress and deformation. This robust foundation ensures the rotor maintains balance and alignment during high-speed or heavy-load operations. As a result, motors equipped with steel shaft magnetic rotors achieve longer service life and greater reliability, particularly in demanding applications like robotics, EV powertrains, and CNC machinery.

2. Enhanced Magnetic Performance

By integrating high-strength permanent magnets with a precision-machined steel shaft, these rotors generate strong, consistent magnetic fields. This enables efficient magnetic coupling with the stator, resulting in improved torque output, reduced energy losses, and smoother motor control. Such performance characteristics are vital for brushless DC motors, permanent magnet synchronous motors (PMSMs), and servo drives.

3. Compact and Customizable Design

Steel shaft magnetic rotors support a wide range of customization options, including shaft length, diameter, magnet positioning, and rotor topology. This design flexibility allows engineers to meet specific installation requirements without sacrificing motor performance. Compact configurations are especially valuable in systems where space is limited, such as drones, electric tools, or integrated drive units.

4. Cost-Effective Manufacturing and Assembly

Compared with complex rotor types that require laminated cores or multi-material assemblies, steel shaft magnetic rotors are simpler to produce and assemble. Modern CNC machining and dynamic balancing technologies allow for precise, scalable production with consistent quality. This not only shortens lead times but also helps reduce overall manufacturing costs—particularly beneficial for OEM production.

5. Wide Application Versatility

Thanks to their robust construction and stable magnetic behavior, these rotors are suitable for a broad spectrum of motor-driven systems. They perform reliably in diverse environments, including electric vehicles, HVAC compressors, automation equipment, medical devices, and renewable energy systems. Their adaptability supports both low-speed torque-heavy applications and high-speed precision motors.

Conclusion

The Steel Shaft Magnetic Rotor combines structural integrity, efficient magnetic performance, and design flexibility to meet the evolving demands of modern electric motor systems. Its versatility and reliability make it an ideal choice for engineers and product developers seeking optimal performance in high-demand scenarios.

If you're developing a new motor project and require a dependable rotor solution, our engineering team provides customized Steel Shaft Magnetic Rotors tailored to your specifications. We offer full OEM/ODM support, precise manufacturing, and technical guidance to ensure your product's success.

Get in touch with us today to learn more or request a custom quote.

E-mail:martin@abm-magnetics.com

Understanding the Role of the Steel Shaft Magnetic Rotor in High-Performance Motors

www.abm-magnetics.com

ABM Magnetics Co. Ltd