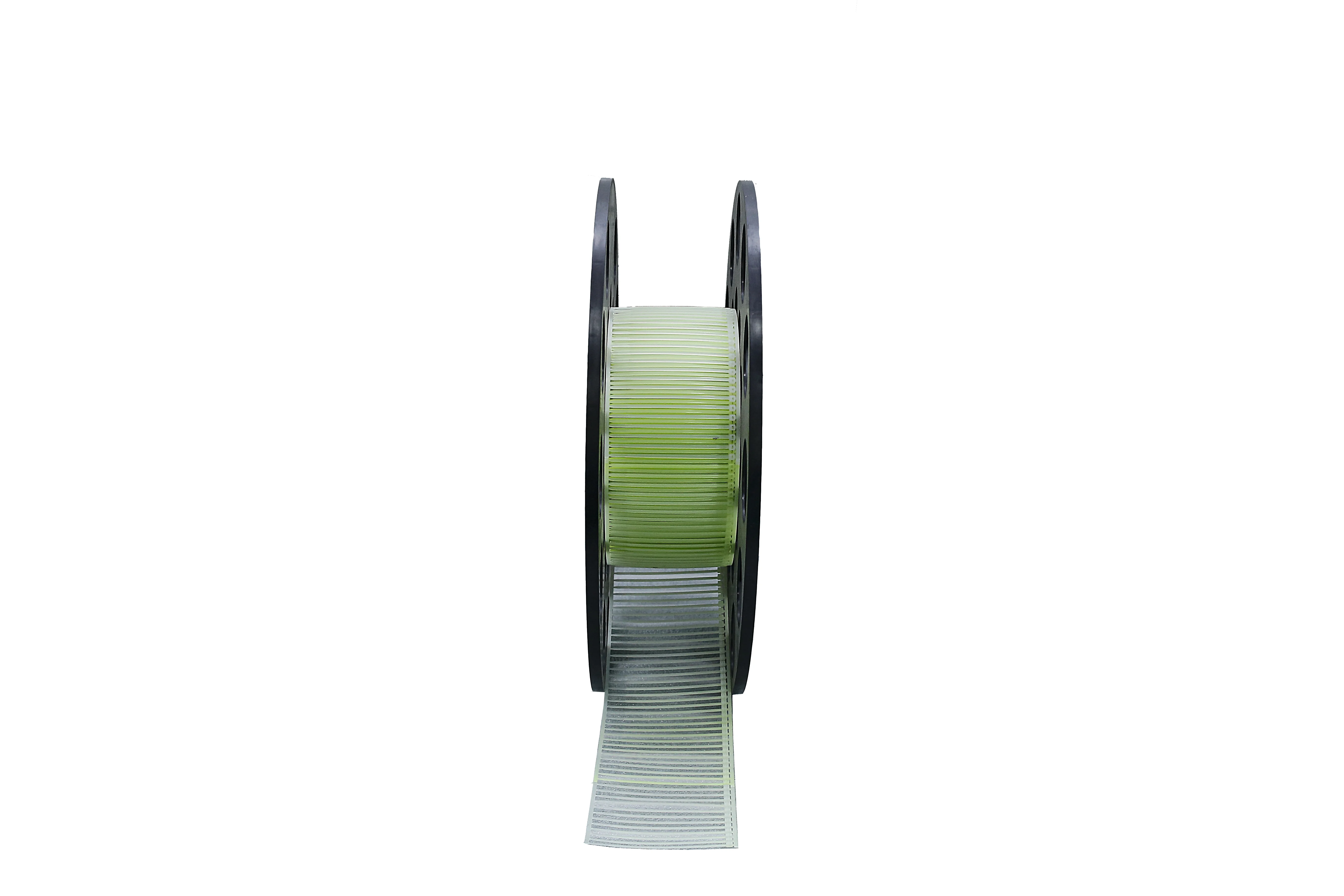

In the world of precision engineering, transmission components play a critical role in the efficiency, reliability, and longevity of mechanical systems. Among these components, the 2GT circular arc pulley stands out for its ability to deliver precise motion control and low-backlash performance, making it ideal for applications such as 3D printing, CNC machinery, robotics, and automation.

Selecting the right 2GT pulley isn’t just a matter of matching dimensions. It requires an understanding of material quality, tooth profile accuracy, manufacturing standards, and compatibility with your specific application. This is where Hetuoda Machinery Manufacturing, a trusted expert in high-precision transmission components, offers a competitive edge.

What Is a 2GT Circular Arc Pulley?

The “2GT” refers to a specific timing belt profile used in synchronous transmission systems. The "2" denotes a 2mm pitch, and "GT" stands for “Gates Tooth”, a profile designed for precise motion control. The circular arc profile offers better meshing and reduced backlash compared to trapezoidal alternatives, making it especially useful in high-accuracy environments.

Key Factors to Consider When Choosing a 2GT Circular Arc Pulley

1. Precision in Tooth Profile

The effectiveness of a 2GT pulley depends heavily on the accuracy of its tooth profile. Any deviation can result in slippage, vibration, or misalignment in the drive system. Hetuoda Machinery Manufacturing uses advanced CNC machining and rigorous inspection processes to ensure that each pulley is produced to tight tolerances, guaranteeing stable transmission performance.

2. Material Selection

Common materials for 2GT pulleys include aluminum alloy, steel, and plastic composites, depending on the weight, strength, and environmental conditions of the application.

-

Aluminum is lightweight and corrosion-resistant.

-

Steel offers superior durability and is ideal for high-load systems.

-

Plastic may be used in low-load, cost-sensitive applications.

Hetuoda offers a wide range of custom material options, allowing OEM clients to choose the best match for their operational environment.

3. Bore and Hub Type

Pulleys come with different bore styles such as pilot bore, tapered bore, or finished bore with keyway and set screws. The right choice depends on your shaft design and torque requirements. Hetuoda provides custom machining services to meet exact bore and hub specifications, including OEM customization.

4. Flange Design and Belt Compatibility

The flange prevents the timing belt from slipping off during operation. Depending on the system orientation and belt type, you may need single-flange, double-flange, or flangeless pulleys. The 2GT pulley must also perfectly match the width and pitch of the GT2 timing belt used in the drive system.

With years of experience in belt drive systems, Hetuoda ensures all components—including pulleys, tensioners, and gear assemblies—are fully compatible.

5. Surface Treatment

To extend pulley lifespan and performance, surface treatments such as anodizing, black oxide coating, or electroplating may be applied. Hetuoda offers a range of finishing services to improve wear resistance, corrosion protection, and aesthetic appearance.

Why Choose Hetuoda Machinery Manufacturing?

As a professional manufacturer of high-precision mechanical transmission components, Hetuoda Machinery Manufacturing specializes in the design and production of:

-

Timing pulleys (2GT, 3GT, 5GT, and more)

-

Gear plates and gear wheels

-

Tensioners and mechanical bushings

-

Custom machined parts for automation and power transmission systems

In addition to its standard product catalog, Hetuoda provides OEM and customized manufacturing services to meet the unique requirements of clients across diverse industries including automation, machinery, robotics, and aerospace.

With a commitment to precision, durability, and customer-specific solutions, Hetuoda has built a solid reputation for technical excellence and reliable service in both domestic and international markets.

Final Thoughts

Selecting the right 2GT circular arc pulley is essential for achieving smooth, accurate, and long-lasting performance in your transmission systems. With multiple variables to consider—material, precision, bore size, and belt compatibility—partnering with an experienced manufacturer like Hetuoda Machinery Manufacturing ensures your components are engineered to perform under real-world industrial conditions.

Whether you're developing a new automation system or upgrading an existing machine, Hetuoda can deliver the precision parts and custom solutions you need to keep your operations running efficiently.

www.cdepulley.com

Suzhou Hetuoda Machinery Manufacturing Co., Ltd.