In the world of modern manufacturing and infrastructure, industrial stainless steel pipes are fundamental components that support a wide range of applications — from construction and energy to automotive and chemical processing. Their strength, corrosion resistance, and versatility make them the preferred choice in many demanding environments.

At TORICH, a professional manufacturer and supplier specializing in steel pipe materials, we are committed to delivering high-quality solutions that meet the rigorous standards of industries worldwide. In this article, we explore the key features and materials of industrial stainless steel pipes and why TORICH stands out as your trusted partner.

What Are Industrial Stainless Steel Pipes?

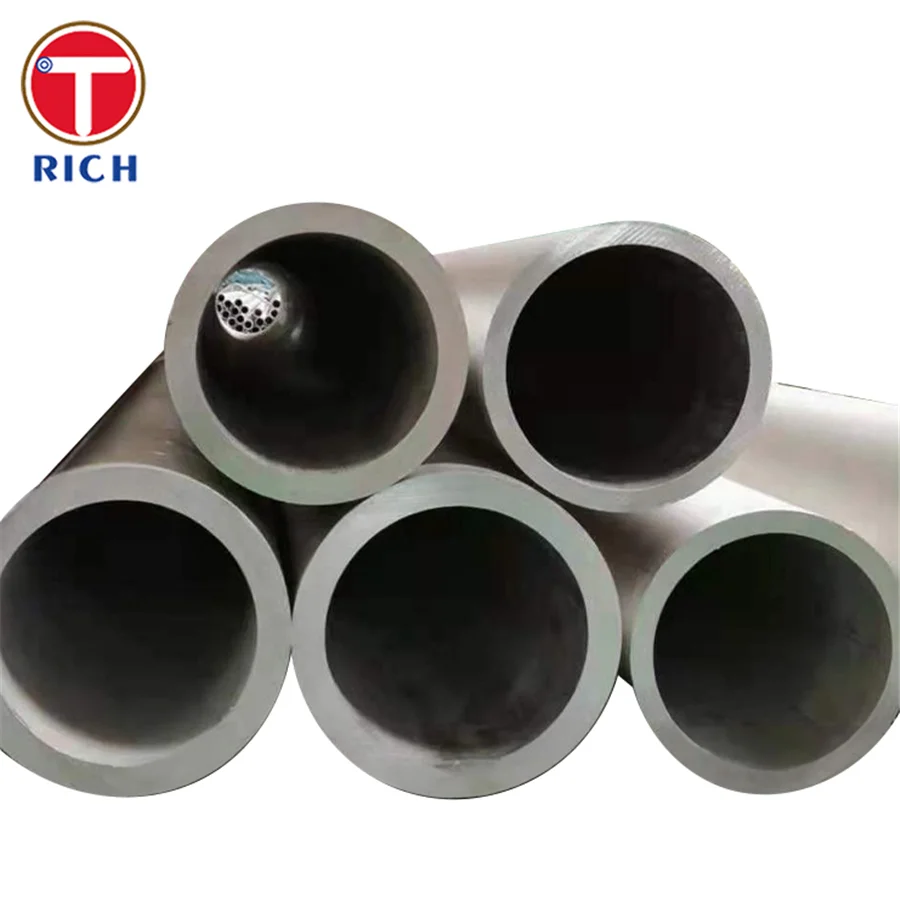

Industrial stainless steel pipes are hollow tubes made primarily from stainless steel alloys, designed for transporting fluids, gases, and solids in a wide range of industrial settings. Unlike ordinary steel pipes, stainless steel pipes offer superior corrosion resistance, durability, and strength, which makes them ideal for challenging environments such as marine, chemical, and high-temperature applications.

Key Features of Industrial Stainless Steel Pipes

1. Corrosion Resistance

One of the defining characteristics of stainless steel is its outstanding resistance to corrosion. Thanks to the chromium content (typically at least 10.5%), a passive layer forms on the steel’s surface, protecting it against oxidation and corrosive substances like acids, alkalis, and chlorides.

Application: Essential in chemical processing, food and beverage production, and marine environments.

Benefit: Longer lifespan and reduced maintenance costs.

2. High Strength and Durability

Industrial stainless steel pipes offer exceptional mechanical strength while maintaining ductility and toughness. This makes them suitable for high-pressure and high-temperature applications.

Application: Oil and gas pipelines, structural applications, and power generation.

Benefit: Withstands harsh operating conditions without cracking or deforming.

3. Temperature Resistance

Stainless steel maintains its structural integrity across a wide range of temperatures, from cryogenic conditions to extreme heat.

Application: Heat exchangers, boilers, and exhaust systems.

Benefit: Reliable performance even under thermal cycling or extreme temperatures.

4. Hygiene and Cleanability

Stainless steel’s smooth surface makes it highly sanitary and easy to clean, which is why it’s favored in industries like pharmaceuticals, food processing, and water treatment.

Application: Water pipes, dairy processing lines, pharmaceutical production facilities.

Benefit: Reduces contamination risks and ensures compliance with health standards.

5. Aesthetic Appeal

Besides its functional benefits, stainless steel also offers an attractive, shiny finish that remains visually appealing over time, making it a popular choice for architectural and decorative applications.

Application: Building façades, handrails, and public infrastructure.

Benefit: Combines form and function without compromising performance.

6. Recyclability and Sustainability

Stainless steel is 100% recyclable, which makes it a sustainable choice for industries looking to minimize their environmental footprint.

Application: Green building projects and sustainable infrastructure.

Benefit: Supports corporate social responsibility (CSR) initiatives and green certifications.

Common Materials Used for Stainless Steel Pipes

The choice of material significantly impacts the performance of industrial stainless steel pipes. Here are some commonly used stainless steel grades:

1. 304 Stainless Steel

Features: Excellent corrosion resistance, good formability, and weldability.

Applications: Food processing, chemical containers, architectural projects.

2. 316 Stainless Steel

Features: Superior corrosion resistance due to the addition of molybdenum, especially against chlorides and marine environments.

Applications: Marine applications, pharmaceutical equipment, chemical processing.

3. 321 Stainless Steel

Features: Stabilized with titanium, offers excellent resistance to intergranular corrosion after welding.

Applications: Aerospace components, exhaust systems, high-temperature chemical processes.

4. Duplex Stainless Steel (2205, etc.)

Features: Combination of austenitic and ferritic stainless steels, offering higher strength and excellent resistance to stress corrosion cracking.

Applications: Oil and gas industry, offshore platforms, heat exchangers.

5. 904L Stainless Steel

Features: Highly alloyed, excellent resistance to strong acids like sulfuric acid.

Applications: Chemical plants, fertilizer production, seawater handling.

At TORICH, we manufacture and supply a full range of stainless steel pipe materials to meet the diverse requirements of our global clients.

Typical Industrial Applications

Thanks to their versatility, stainless steel pipes are widely used in:

Oil and Gas Pipelines

Chemical and Petrochemical Plants

Power Generation Plants

Food and Beverage Processing Facilities

Pharmaceutical Manufacturing

Automotive Exhaust Systems

Water Treatment and Desalination Plants

Each of these applications requires high-quality piping solutions that guarantee reliability, safety, and cost-effectiveness — qualities that TORICH's products consistently deliver.

Why Choose TORICH?

Choosing the right supplier is critical to ensure the success of your projects. Here's why TORICH is a leader in the field:

Professional Manufacturing: With advanced production facilities and expertise, we manufacture seamless stainless steel pipes, welded pipes, and precision tubes.

Quality Control: Our systematic quality management ensures that every product meets international standards like ASTM, DIN, JIS, and ISO.

Wide Product Range: From industrial piping to precision tubing for specific industries, we offer a comprehensive selection.

Customization Services: Tailored solutions to meet your exact specifications regarding size, thickness, grade, and application needs.

Global Support: Reliable logistics and after-sales services to serve customers around the world.

At TORICH, we combine innovation, precision, and dedication to deliver steel pipe solutions you can trust.

Conclusion

Industrial stainless steel pipes are essential components across numerous sectors due to their durability, corrosion resistance, and versatility. Understanding their key features and material options can help businesses make informed choices for their specific applications.

When you partner with TORICH, you’re choosing a professional manufacturer and supplier with a strong commitment to quality, service, and innovation. Let us help you build the infrastructure and products that shape the future.

Troubleshooting Common Issues with Seamless Cold Drawn Tubes: A Practical Guide

www.torichsteel.com

TORICH