In modern manufacturing, the need for precision, efficiency, and adaptability is greater than ever. As industries evolve and demand increasingly complex components, machining technology must advance to keep pace. Five-axis cradle machining has emerged as one of the most innovative solutions for creating intricate parts across aerospace, automotive, medical, and high-tech sectors. Its ability to address challenges that conventional machining methods struggle with makes it an indispensable asset for manufacturers worldwide.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd., a manufacturer with a strong reputation for producing CNC machining centers, wire cutting machines, EDM machines, milling machines, and other advanced equipment, plays an important role in enabling businesses to leverage cutting-edge machining solutions. Their expertise and product portfolio provide companies with reliable tools to push the boundaries of design and production.

Understanding the Essence of Five-Axis Cradle Machining

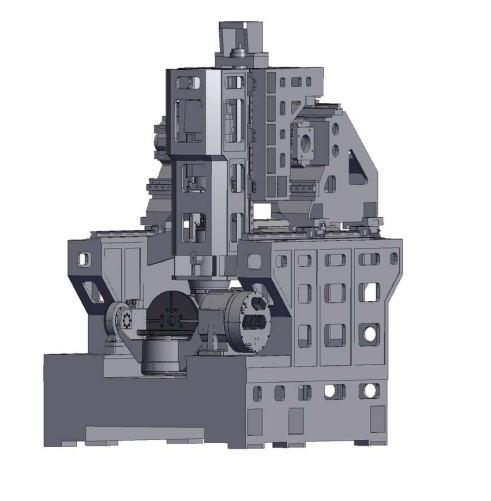

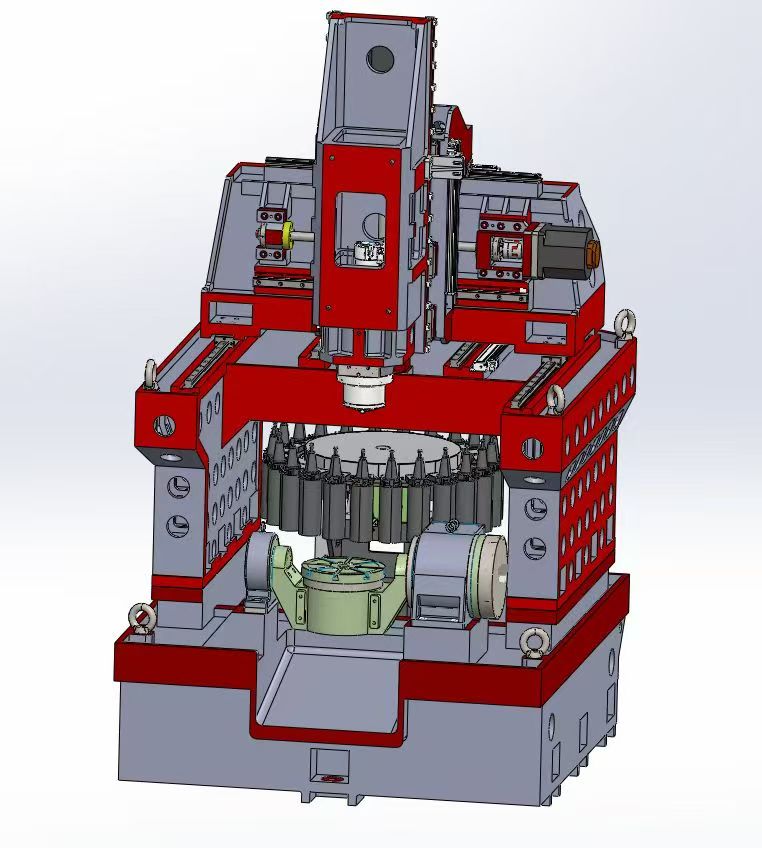

Five-axis cradle machining is not just an incremental improvement over three-axis or four-axis machining. It represents a transformative step forward. By allowing the cutting tool or the part itself to move along five distinct axes, manufacturers gain the flexibility to machine surfaces and angles that would otherwise be inaccessible. This innovation reduces the need for multiple setups, increases accuracy, and saves time.

In cradle-based configurations, the workpiece is often mounted on a rotary cradle, allowing simultaneous tilting and rotation. This design makes it possible to reach undercuts, contours, and complex geometries with ease. For industries where tolerances are measured in microns and shapes are highly intricate, such as turbine blades or orthopedic implants, cradle machining becomes the solution of choice.

Challenges in Manufacturing Complex Parts

Creating complex parts is never straightforward. Engineers and machinists must often overcome obstacles such as limited tool accessibility, long cycle times, and the risk of cumulative error caused by multiple setups. Traditional machining processes can struggle to deliver consistent quality when parts involve compound curves, sharp transitions, or deep cavities.

Furthermore, as designs become more advanced, the need for precision machining escalates. Errors that are acceptable in conventional parts can be catastrophic in critical industries like aerospace or medicine. The demand for smooth finishes, lightweight structures, and optimized strength-to-weight ratios intensifies the complexity of machining.

Five-axis cradle machining addresses these challenges head-on, offering a streamlined path to achieve tight tolerances, better surface finishes, and reduced machining times.

Advantages of Five-Axis Cradle Machining

The benefits of adopting cradle-based five-axis machining extend far beyond efficiency. Some of the most notable advantages include:

Improved Accuracy: By reducing the number of setups, the likelihood of dimensional errors decreases significantly.

Enhanced Surface Quality: The ability to approach surfaces at optimal angles ensures smoother finishes, minimizing the need for post-processing.

Complex Geometry Handling: Intricate parts with undercuts, freeform shapes, and complex contours become manufacturable.

Reduced Production Time: Simultaneous movement along five axes shortens cycle times and increases throughput.

Extended Tool Life: Better cutting angles and reduced tool deflection prolong the lifespan of cutting tools.

These benefits directly translate into lower costs, greater efficiency, and higher customer satisfaction.

Role of Suzhou Zhiquan Electromechanical Equipment Co., Ltd.

As a leading manufacturer, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. provides essential support to industries adopting five-axis cradle machining. Their CNC machining centers and precision equipment form the backbone of production lines that demand uncompromising quality. By integrating advanced technology into their machines, the company helps clients unlock the full potential of modern machining techniques.

Their product range also includes wire cutting machines, EDM forming machines, and milling machines, enabling a comprehensive approach to manufacturing. This versatility allows businesses to create efficient, tailored workflows that combine multiple machining methods for optimal results.

Applications Across Industries

Five-axis cradle machining finds applications in many fields, each with unique requirements:

Aerospace: Manufacturing turbine blades, structural components, and housings with lightweight yet strong designs.

Automotive: Producing engine components, transmission parts, and molds for lightweight, high-performance vehicles.

Medical Devices: Creating implants, prosthetics, and surgical tools with precise geometries for patient-specific needs.

Energy Sector: Machining components for wind turbines, gas turbines, and advanced energy systems.

Consumer Electronics: Producing compact, intricate parts for devices that demand miniaturization and precision.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. supports these industries with machines that deliver the performance, reliability, and precision needed for success.

Integration of Technology and Expertise

Successful cradle machining requires more than advanced equipment. It also demands expertise in programming, tool selection, and process optimization. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software play a crucial role in generating toolpaths that take full advantage of the machine’s capabilities.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. not only delivers machines but also ensures that customers benefit from technical support and guidance. This integrated approach enables companies to shorten the learning curve and maximize productivity.

Sustainability and Efficiency in Machining

Modern manufacturing places emphasis not only on speed and precision but also on sustainability. Five-axis cradle machining contributes to eco-friendly practices by reducing material waste, optimizing tool use, and cutting energy consumption. The reduction in setups and shorter cycle times also help lower the carbon footprint of production.

Manufacturers like Suzhou Zhiquan Electromechanical Equipment Co., Ltd. recognize the importance of sustainability and design machines that balance performance with environmental responsibility.

Driving Innovation Through Collaboration

The future of manufacturing is collaborative. Companies that combine the right equipment, skilled personnel, and innovative design approaches will continue to lead in their fields. By partnering with reliable machine tool manufacturers, businesses gain access to technology that enhances their competitiveness.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. embodies this spirit of collaboration, working closely with clients to understand their unique challenges and provide tailored solutions. Their ongoing commitment to research and development ensures that they remain at the forefront of machining technology.

Conclusion

Five-axis cradle machining represents a significant leap in the ability to solve complex manufacturing challenges. By delivering precision, efficiency, and adaptability, it enables industries to push the limits of what is possible in product design and performance.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd., with its comprehensive range of CNC machining centers, wire cutting machines, EDM machines, and milling equipment, plays an essential role in this transformation. Their contributions help businesses across industries achieve excellence in manufacturing, ensuring that innovation continues to thrive.

Through the combination of advanced machining technology, expert support, and a focus on sustainable practices, five-axis cradle machining sets the stage for a new era of problem-solving in manufacturing.

Key Applications of Five-Axis Cradle Machining Across Industries

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.