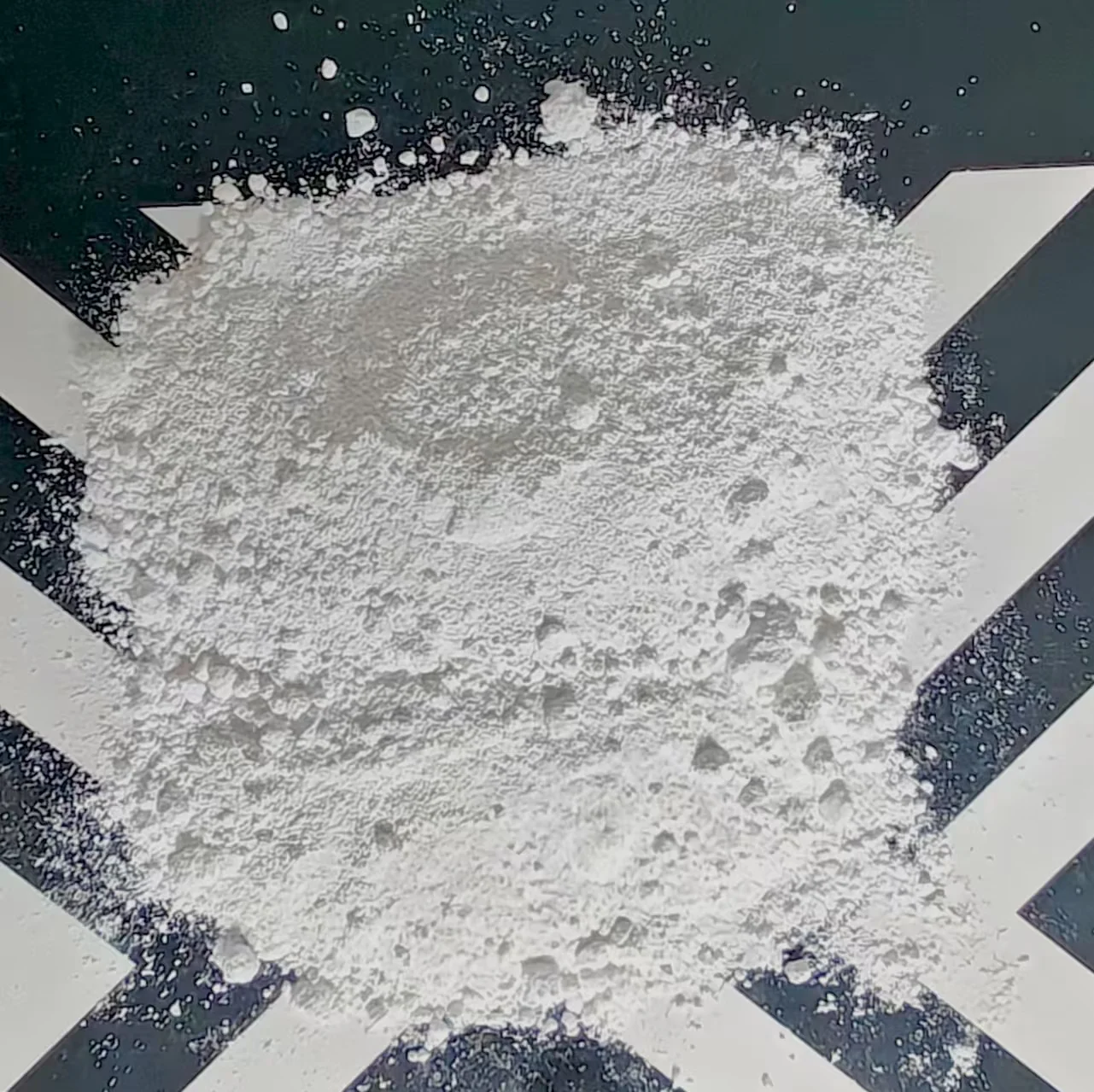

Titanium dioxide remains one of the most influential materials in modern coating engineering. Among its crystal forms, rutile and anatase titanium dioxide in coatings offer distinct performance advantages that shape durability, appearance, and protective behavior. In this blog post, ALATAI, as high quality TiO2 rutile powder manufacturing factory, will share the excellent performance of rutile and anatase titanium dioxide in coatings.

How Rutile Titanium Dioxide in Coatings Enhances Film Strength

Rutile-grade TiO₂ is widely recognized for its high refractive index and exceptional photostability. In architectural, industrial, and protective coatings, these characteristics translate directly into film strength and long-term weather resistance.

Rutile pigments exhibit excellent UV shielding, making them suitable for coatings exposed to harsh sunlight. Their denser crystal structure reduces photocatalytic activity, which in turn prevents premature chalking and maintains surface integrity. Because color retention is a priority in many exterior applications, rutile titanium dioxide provides consistent whiteness longevity even in climates with intense solar radiation.

Manufacturers also prefer rutile for its compatibility with a wide range of binders, including acrylic, polyurethane, and epoxy systems. This compatibility helps maintain gloss, promotes uniform dispersion, and supports the formation of stable films resistant to moisture, corrosion, and chemical degradation.

Why Anatase Titanium Dioxide in Coatings Delivers Superior Brightness

While rutile is prized for durability, anatase titanium dioxide in coatings is valued for its exceptional brightness and blue-white undertone. This makes it ideal for decorative applications requiring high reflectivity and a clean, crisp appearance.

Anatase particles possess a slightly lower refractive index but higher scattering efficiency in the near-UV and visible regions. This optical behavior produces a strong whitening effect, especially desirable in interior coatings, art materials, and specialty finishes. Because interior environments do not expose coatings to severe UV conditions, the lower photostability of anatase becomes less of a concern.

Its softer crystal structure improves ease of dispersion, reducing energy consumption during processing. Moreover, anatase titanium dioxide often contributes to smoother surfaces, making it a preferred choice where visual clarity and brightness are the primary goals.

Rutile and Anatase Titanium Dioxide in Coating Formulations: Key Differences

Selecting between rutile and anatase grades requires understanding the functional trade-offs each brings to a coating system. Their contrasts extend beyond appearance, influencing durability, protective capacity, and application costs.

-

Photostability

Rutile offers superior resistance to UV-induced degradation. Its low photocatalytic activity protects binders from oxidation. Anatase, by contrast, exhibits higher photocatalytic behavior, which can lead to surface chalking under sunlight. -

Optical Properties

Anatase delivers brighter, bluer whiteness, while rutile provides more neutral whiteness and stronger hiding power due to its higher refractive index. -

Dispersion Characteristics

Anatase generally disperses more easily, reducing pigment-grinding time. Rutile grades often include surface treatments to improve dispersibility and reduce agglomeration. -

Cost Considerations

Anatase pigments are typically more economical, making them appealing for interior applications and cost-sensitive markets. Rutile grades, especially surface-treated versions, command higher prices due to their long-term protective benefits.

These distinctions allow formulators to tailor performance based on functional requirements rather than relying on a single universal pigment.

Functional Roles of Titanium Dioxide Crystal Forms in Protective Coatings

Whether used alone or together, rutile and anatase serve different roles in enhancing protective coatings. Their contributions span opacity, resilience, and environmental resistance.

Rutile serves as the backbone of weather-resistant coatings, forming a barrier that shields substrates from UV-driven degradation. Its stable crystal structure defends the polymer matrix, preventing microcracking and gloss loss. This is crucial for marine, automotive, and industrial applications where longevity defines product value.

Anatase, on the other hand, plays a dominant role in decorative and specialty surfaces. Its ability to deliver brilliant whiteness improves visual impact, which is essential in premium indoor paints and artistic coatings. In some formulations, anatase is also incorporated to achieve higher reflectivity for energy-saving interior spaces.

In hybrid systems, combining both forms can balance optical and durability requirements, providing unique performance benefits unattainable through a single crystal type.

Balancing Rutile and Anatase Titanium Dioxide in Architectural Coatings

Architectural coatings require a balance of weather resistance, opacity, and visual appeal. Using the appropriate ratio of rutile and anatase allows manufacturers to craft formulations that perform effectively indoors and outdoors.

Rutile is indispensable in exterior coatings due to its photostability. It prevents fading and maintains structural integrity in environments exposed to sunlight, moisture, and pollutants. By shielding polymers from UV energy, it reduces maintenance costs for residential and commercial buildings.

Anatase, when used in interior wall paints, enhances brightness and improves light scattering, creating a vivid appearance under artificial lighting. Combining rutile in small proportions can further improve opacity without compromising brightness.

This strategic balance supports energy-efficient spaces, enabling interior walls to reflect more light and reduce the need for high-wattage illumination.

Industrial Use Cases for Rutile and Anatase Titanium Dioxide in Coatings

Beyond architecture, both forms play distinct roles in industrial settings.

Rutile Applications

-

Heavy-duty protective coatings

-

Marine paints

-

Automotive OEM and refinishing systems

-

Anti-corrosion primers

-

Chemical-resistant linings

In these uses, the durability and UV stability of rutile protect equipment and structures from environmental degradation and chemical exposure.

Anatase Applications

-

Interior decorative coatings

-

Wood coatings requiring high brightness

-

Paper and art finishes

-

Low-VOC coating systems requiring easy dispersion

Anatase remains an economical option where optical clarity is more critical than extreme weather performance.

How Titanium Dioxide Crystal Forms Influence Coating Performance Metrics

Rutile and anatase influence multiple performance parameters, including:

-

Opacity and Hiding Power

Rutile creates stronger light scattering at visible wavelengths, improving hiding power with lower pigment loading. -

Whiteness and Tone

Anatase produces a bluer tone that enhances brightness in decorative products. -

Chalking Resistance

Rutile’s lower catalytic activity protects against chalking, enabling longer lifecycles for exterior coatings. -

Gloss Retention

High-gloss exterior surfaces rely on rutile to maintain reflective quality over years of UV exposure. -

Processing Behavior

Anatase’s softer structure simplifies dispersion, helping manufacturers reduce energy demand during production.

Each attribute affects the final coating, from aesthetics to lifecycle cost.

Selecting Between Rutile and Anatase Titanium Dioxide for Coating Systems

Choosing the right crystal form depends on functional priorities, environmental conditions, and performance expectations.

-

Use rutile when UV resistance, weatherability, and long-term protection are essential.

-

Use anatase when brightness, interior aesthetics, and cost efficiency matter most.

-

Use hybrid systems when formulations require optimized opacity, balanced tone, and moderate durability.

Proper selection ensures coatings align with customer expectations and regulatory requirements without sacrificing performance or efficiency.

Future Trends in Rutile and Anatase Titanium Dioxide for Next-Generation Coatings

Advances in pigment surface treatment, dispersion technology, and nanostructuring are reshaping the role of titanium dioxide in the coatings sector.

Modern rutile pigments are increasingly engineered with multifunctional coatings that reduce photocatalytic activity, enhance moisture resistance, and improve compatibility with low-VOC binders. These enhancements make them better suited for environmentally responsible, long-lasting coatings.

Meanwhile, anatase pigments are undergoing refinement to boost brightness and reduce unwanted reactivity. New hybrid systems are emerging, combining rutile stability with anatase optical clarity, offering a path to coatings that remain visually striking and resilient across diverse environments.

As sustainability becomes central to the coating industry, both crystal forms will continue evolving to meet the demands of high-efficiency, low-impact product development.

www.titanmastech.com

ALATAI